water soluble label paper

Water soluble label paper:

Non woven water soluble label, paper water soluble label, water soluble sticker pasted on food plates or storage containers, can clearly indicate the product name and date; Labels that are well labeled do not require special cleaning, as the water-soluble label surface material is based on chemically modified cellulose from plant fiber raw materials and copied into starch, without wood fibers, and does not require special cleaning. The adhesive and label are completely dissolved in hot or cold water, leaving no sticky residue. It has the advantages of being fast, easy to clean, energy-saving, water-saving, and environmentally friendly

Attention:

Store at 201 ℃ in polyethylene cling film and 50% RF with a minimum operating temperature of -6 ° C; C. Water soluble paper labels are highly sensitive to moisture, relative humidity, and temperature. Exposure to environmental conditions higher than recommended will accelerate degradation and decomposition

Applied to the food and fast food industry, suitable for producing labels and markings on food salt, kitchen and bathroom utensils, turnover boxes, water toys, sports equipment, boats, and recyclable containers. Environmentally friendly and easily removable. This type of label paper has great potential in some new and innovative applications for printing industry publishers. Many label production companies have already liked this label paper in its beta testing process

1) This label can be cut into various sizes according to the requirements of regular paper

2) It can be printed like a regular label

3) At room temperature, it can dissolve immediately after washing with water

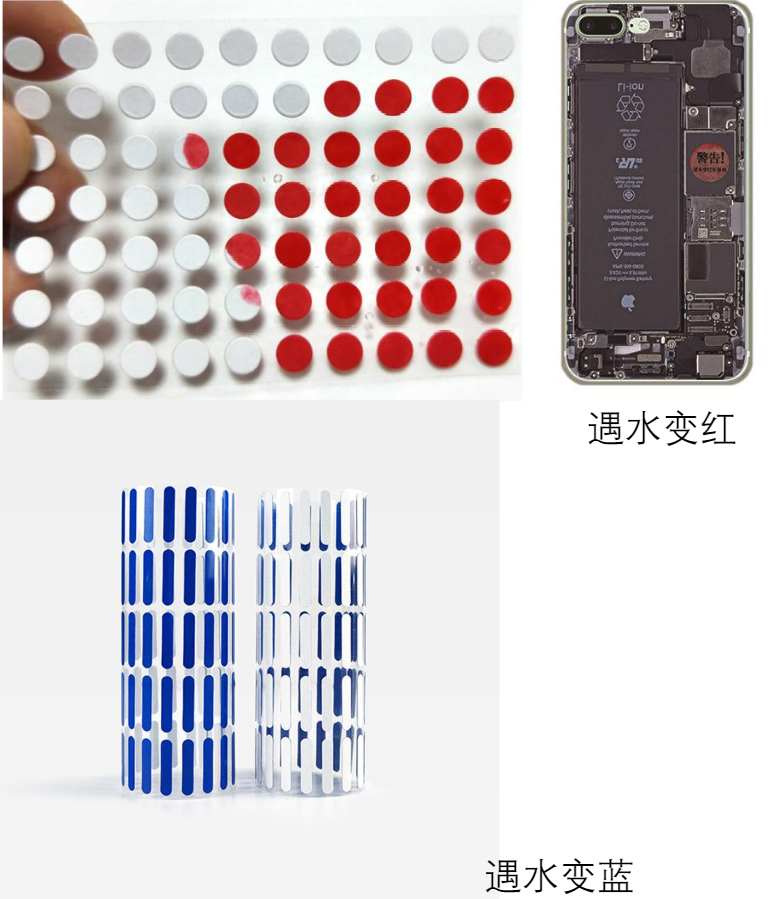

Red label paper when exposed to water

Turning red when in contact with water is a warranty service for products such as mobile phones, batteries, electronics, and electrical LCDs that are difficult to identify or incorrectly identified after being damaged by water, and do not meet the conditions for control. At the same time, turning red when in contact with water is also a new type of product developed for identifying water ingress in long-distance transportation goods and providing legal basis for claims. The main function of the water turning red label is to show that when the substrate is completely exposed to water, the surface will turn red when exposed to water, and the color will be significantly different from before, and irreversible

Characteristics of turning red when encountering water

The main function of turning red when in contact with water is that when the substrate is completely exposed to water, the surface will turn red when in contact with water, and the color will be significantly different from before, and irreversible

2. It turns red when exposed to water. Based on the critical humidity at which the product is damaged after exposure to water, it can be designed to change color according to the preset relative humidity or only when completely immersed in water

3. There are two main types of waterproof labels that turn red when exposed to water: water diffusion: when the label turns red when exposed to water, the original pattern on the label will quickly spread around it. Color development in water: When the water turns red label is immersed in water, the original color of the water turns red label will quickly spread and completely change to another preset color

4. It turns red when exposed to water and can be used in electronic products such as mobile phones, lithium batteries, MP3 players, etc

When in contact with water, it turns red. Scope of use

The anti-counterfeiting label that turns red when encountering water can accurately detect abnormal results when entering the liquid. When abnormalities occur, the responsible party can be clearly identified to protect the rights and interests of both merchants and consumers. Turning red when in contact with water has a strong sensitivity to humidity and can accurately display the degree of moisture on the surface. Turning red when in contact with water is mainly used to test the identification of product entry and can have an aesthetic effect. Clearly define the responsibility for circuit damage caused by liquid ingress in electronics, circuits, batteries, mobile phones, etc

Laser specific printing paper stickers

The commonly used material for laser printers in the market is adhesive paper, but the high temperature and speed of the printer make the pressure-sensitive adhesive prone to adhesive leakage and damage under high temperature, while dedicated laser printing paper stickers can solve this problem

Offset paper, also known as writing paper, is made by coating the back with a bottom layer to make the adhesive more firm. The CCK release paper on the back of the material is resistant to high temperatures and does not wrinkle, making the paper entry and exit of the laser printer smoother, without jamming or glue leakage. Generally, monochrome printing or printing is used for barcode information labels, and laser printers can also be selected for direct writing. As long as the design does not require narrow angle turns, the printing effect can be better achieved

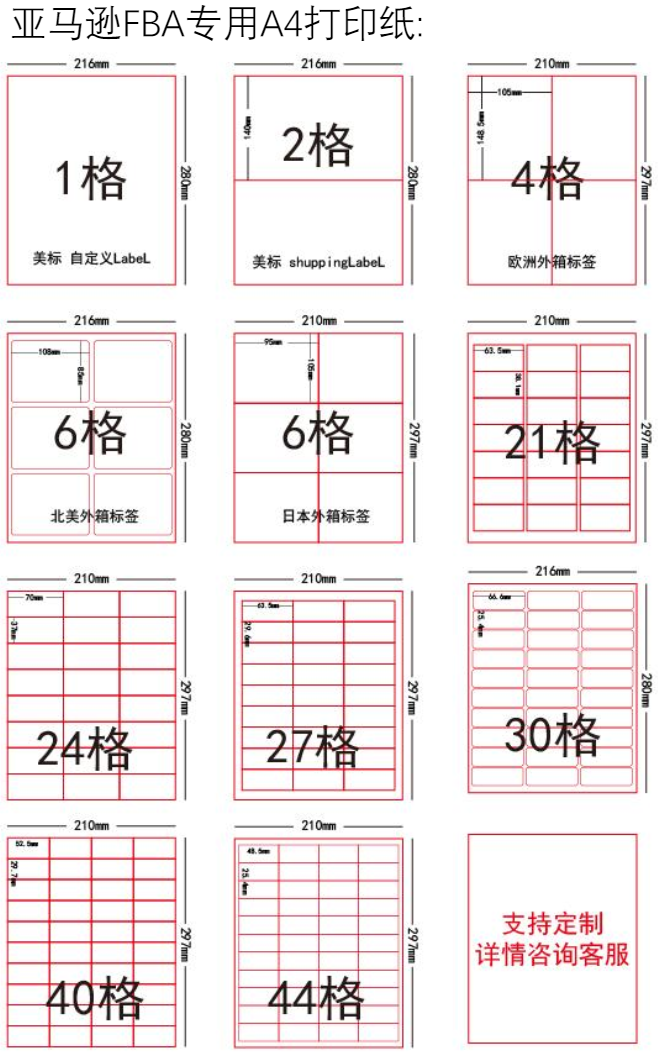

A4 adhesive printing paper

Biodegradable stickers

OwnLikes has developed Cellulose paper film products in response to the requirements of sustainable development, circular economy, and environmental plastic removal in the packaging market, combining advanced technologies at home and abroad< br /> Recycling: Product raw materials are sourced from recycled ingredients, renewable resources: Product raw materials are sourced from biomass resources such as forests, plants, etc., rather than petroleum. Reduction: Product thinning, weight reduction, and plastic reduction, using less raw materials. Monomer structure replaces composite structure. Biodegradable: biodegradation, industrial degradation, oxygen degradation, photodegradation. High transparency, good tensile strength. Innovative coating process enhances printing adaptability and moisture resistance. FSC certification (certificate number RINA-CO-001475) SGS bovine degradation certification (SO certificate number: GZIN2111064903MR)

PE winding cable label

Wrapped cable labels, also known as covered cable labels, consist of two parts. The upper part is a white or colored printed coating, and the lower part is a transparent protective film. When in use, the printed area can be covered with a transparent protective film for protection. The transparent protective film should have sufficient length to wrap the cable in one or a half turns, and the adhesive position should be within 3-10 centimeters from the cable joint. The label content should be clear and visible, and the label should be made of a medium that is not easily detached. The diameter of the cable determines the length of the required wrapped label

Product Features

1. A material specifically designed for cable identification, which is a matte treated transparent polyolefin film with acrylic pressure-sensitive adhesive

2. Leave a blank area for heat transfer printing

3. The appearance is uniform, transparent, and has good waterproof and oil resistant properties

4. The effect is natural and harmonious, with excellent performance

5. Used in situations where PE label materials cannot be used due to environmental requirements

6. After laminating, there are multiple colors available for selection, including red, orange, yellow, green, and green

7. Various specifications can be customized according to customer requirements

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.