Temperature Indicating Recorder Labels

Temperature Indicating and Recording Labels are commonly referred to as "color-changing temperature measurement patches" in China, while in foreign countries, they are generally known as "Temperature Indicating Recorder Labels", also called temperature indicating strips, temperature wax strips, color-changing temperature indicating strips, temperature labels, surface temperature tags, temperature-sensitive test papers, thermosensitive papers, temperature measurement papers, temperature test strips, temperature indicating bars, temperature bars, temperature measurement strips, temperature measurement stickers, thermal/heat-sensitive/thermo-inductive indicators, temperature indicating papers, temperature sensors, test temperature wax strips, color-changing temperature measurement patches, stickers, overheat monitoring, and temperature recording phase sequence indicating labels. This is a relatively novel temperature measurement technology that employs temperature-sensitive color-changing measurement techniques. It can be attached to the equipment being measured, changing color or displaying temperature digits as the equipment's temperature varies, thereby allowing one to grasp the temperature changes of the equipment.

The mechanisms behind these labels vary and are not all the same, but they all involve a series of chemical and physical changes that occur when an object is heated, leading to changes in the molecular structure and, consequently, changes in the color of reflected light. For example, crystal form transformation, sublimation, dehydration, oxidation, and decomposition can cause shifts in the frequency bands of light scattering.

Advantages of Temperature Indicating and Recording Labels

-

It is particularly suitable for measuring the temperature of components, outer surfaces, and objects in life-threatening environments where ordinary thermometers cannot or are difficult to use. Examples include temperature measurements of transistors, integrated circuits, chemical reaction tanks, engine bearings, conductor buses, switches, joints, transformers, etc.

-

It facilitates inspection patrols. When the temperature changes, it triggers a color change, allowing people to take measures promptly to prevent accidents and nip potential hazards in the bud.

-

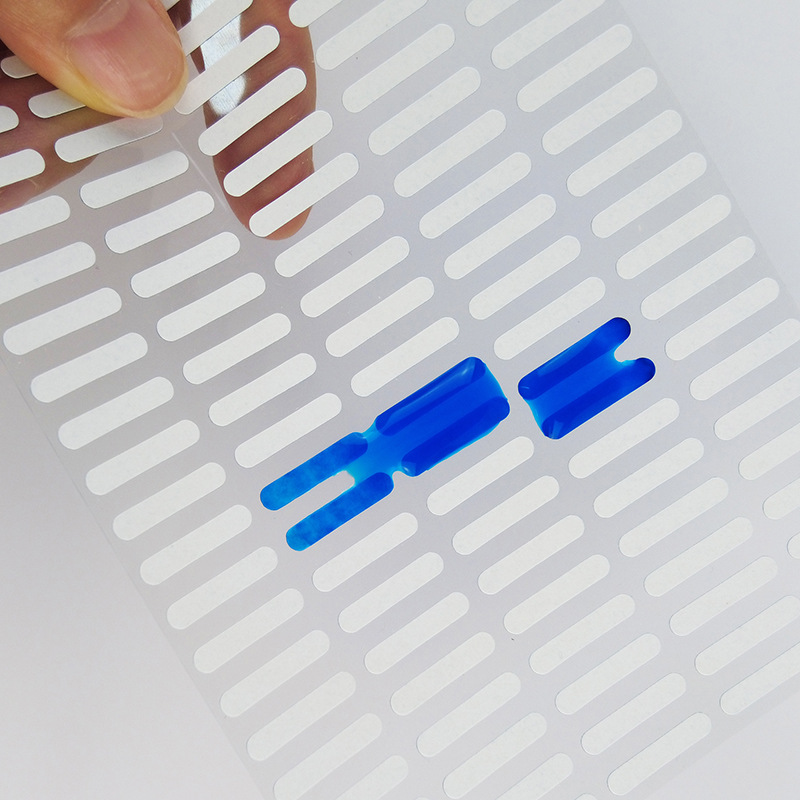

The product is lightweight, portable, and easy to install. For example, the temperature-sensitive color-changing patch with adhesive is very convenient to use; simply peel it off and stick it on.

-

It is more economical. When measuring the same number of temperature measurement points, it saves costs compared to other temperature measurement tools.

Temperature Indicating and Recording Label Classification and Selection

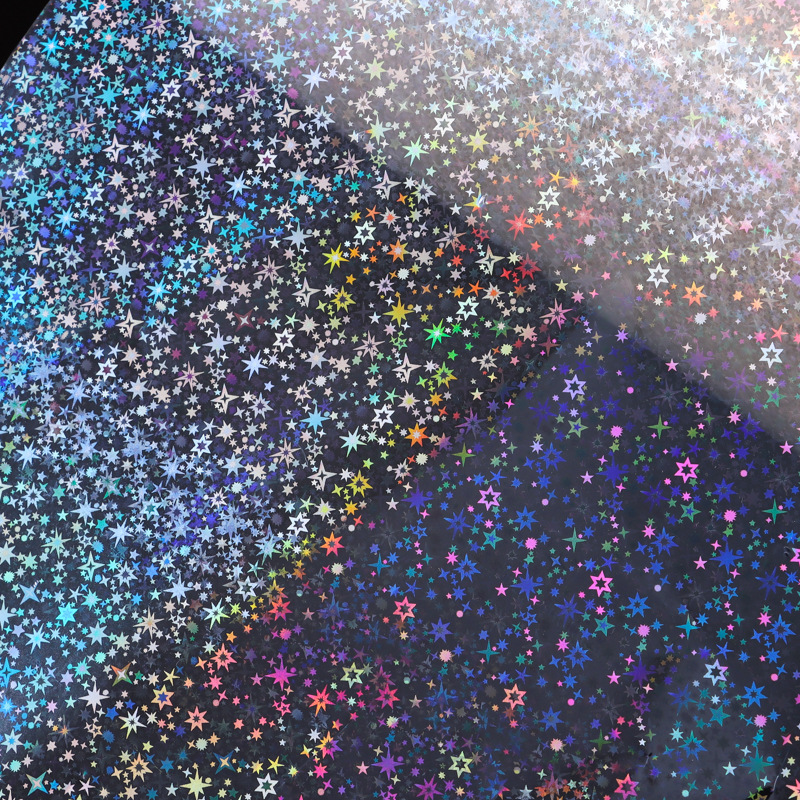

Based on color changes, they can be classified as single-color-change or multi-color-change, as well as reversible or irreversible. For instance, liquid crystal color-changing products can exhibit color changes such as red, green, and blue within a specified small temperature range, with different colors corresponding to different temperatures. As the temperature returns to normal, the color also reverses, belonging to the reversible multi-color-change series. On the other hand, products that only undergo a single color change fall into the single-color-change series. If the color does not revert, it is classified as irreversible. In most industrial productions, it is impractical to have someone constantly present at the temperature measurement site, relying instead on patrols for observation. For such sites, irreversible color-changing temperature measurement products are required. Their color, once changed due to temperature rise, does not revert, thus preserving the record of overtemperature incidents and potential hazards. This feature has made them popular among users. In certain situations, people hope to combine the advantages of both reversible and irreversible products, leading to the emergence of products that are both reversible and capable of recording.

To better assist users in selecting temperature measurement products that suit their needs, there are generally temperature patches available in various grades, including 50℃, 55℃, 60℃, 65℃, 70℃, 75℃, 80℃, 85℃, 100℃, and 120℃, as well as patches for higher or lower temperatures. For areas where the temperature standard is already clearly defined, using a single temperature point white-to-red color-changing patch is more cost-effective and straightforward for detection. If the observation distance is not far and the lighting is good, a 1.5cm x 1.5cm patch can be chosen; if the observation distance is far and the lighting is poor, a larger size of 3cm x 3cm patch can be selected. Circular patches are also an option. The color choices are not limited to white-to-red; there are also options such as white-to-yellow, white-to-green, and white-to-black. For those who desire a broader temperature measurement range or have not yet determined the specific temperature standard, multiple temperature patches can be used simultaneously. To distinguish between different temperatures, patches of different sizes, colors, or positions can be used to indicate the variations in color-changing temperatures. For example, using the YDX678 model or combining 60℃ white-to-black, 70℃ white-to-green, and 80℃ white-to-red patches in the same area, after exceeding the temperature, different colors will represent different temperatures. Alternatively, a combination of a 70℃ 2cm x 2cm small white-to-red patch and a 80℃ 3cm x 3cm large white-to-red patch can be used to indicate two different temperatures. One can also choose a freely cuttable white-to-red patch and cut it into different shapes with scissors to represent different temperatures according to personal recognition.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.