Corrosion resistant label

Corrosion resistant labels are special label materials designed to cope with various chemical corrosion environments. This type of label not only has excellent corrosion resistance to common chemicals such as acid and alkali, acetone, and washing water, but can also be customized for other corrosive chemicals according to specific customer needs, ensuring the stability and readability of the label in specific environments. Its material is mainly PET (polyethylene terephthalate), because PET material has excellent chemical stability, mechanical strength, and weather resistance, which can effectively resist the erosion of various chemical substances. In addition, the key to corrosion-resistant labels lies in their special coating and adhesive. Coating is the first line of defense to protect labels from chemical corrosion and must be able to withstand long-term corrosion. And glue is responsible for ensuring that the label can be firmly attached to the target object in various harsh environments, without falling off or losing its stickiness, thus ensuring the long-lasting and clear identification.

Corrosion resistant adhesive label

Corrosion resistant adhesive labels have the characteristics of acid and alkali resistance, corrosion resistance, chemical solvent resistance, high temperature resistance, moisture resistance, etc., and are widely used in harsh environments such as high temperature, high humidity, acid and alkali. Waterproof, corrosion-resistant, and high-temperature resistant materials and adhesives are commonly used, and have been tested to resist the corrosion of various chemicals such as bleach, brake fluid, alcohol, gasoline, diesel, acetone, isopropanol, MEK, petroleum solvent oil, penetrating oil, xylene, etc. Suitable for fields such as chemical engineering, industrial machinery, energy and power, underground pipeline networks, product traceability, logistics transportation, biological experiments, outdoor labeling, location patrols, and automotive engine labeling that require use in harsh environments such as high temperature, humidity, acidity, and alkalinity

Optional materials:PET, PVC, synthetic paper, etc

Label features:Corrosion resistant labels are waterproof, oil resistant, acid and alkali resistant, corrosion-resistant, resistant to chemical solvents, not easy to lift and fall off, with clear printing, bright colors, good glossiness, not easy to fade, smooth surface, uniform thickness, good flexibility, not easy to tear, etc

Application scope:Chemical and chemical engineering, industrial machinery, energy and power, underground pipeline network, product traceability, logistics transportation, biological experiments, outdoor identification, location patrol, automobile engine identification, etc

Chemical corrosion resistance label

This is a type of label material designed specifically for chemical corrosion environments, with adhesive being its most unique feature. In addition to common applications such as acid and alkali resistance, acid and alkali resistance, and washing resistance, specialized label materials can also be customized according to specific corrosive chemicals required by customers.

This type of label comes with a specially developed coating that can be directly printed using a general-purpose office laser printer, providing excellent printing results. A professionally formulated adhesive that can withstand the instantaneous high temperature during laser printing, avoiding glue overflow. This label is extremely convenient to use, greatly reducing the cost of barcode equipment investment for chemical enterprises. The overall size of the label is the same as that of regular printing paper, making it the preferred choice for major chemical companies worldwide!

Light blocking sticker label

Light blocking stickers are a type of high gloss white surface material, with black/gray/dark blue adhesive backing. The biggest feature of these stickers is that they do not transmit light when applied to the product being covered, and can completely cover the content that needs to be covered

Environment

Operating temperature: -20-100 ℃ C

Minimum pasting temperature: 10 ℃ Product shelf life: 1 year (not pasted)

Product advantages

1. The viscosity is stable and does not overflow

2. The product has excellent shading performance

3. The adhesive has good stability and a long holding force

Light shielding labels are widely used in industries such as lighting, smart home, and more. Simply put, they can be used in various industries, and so on

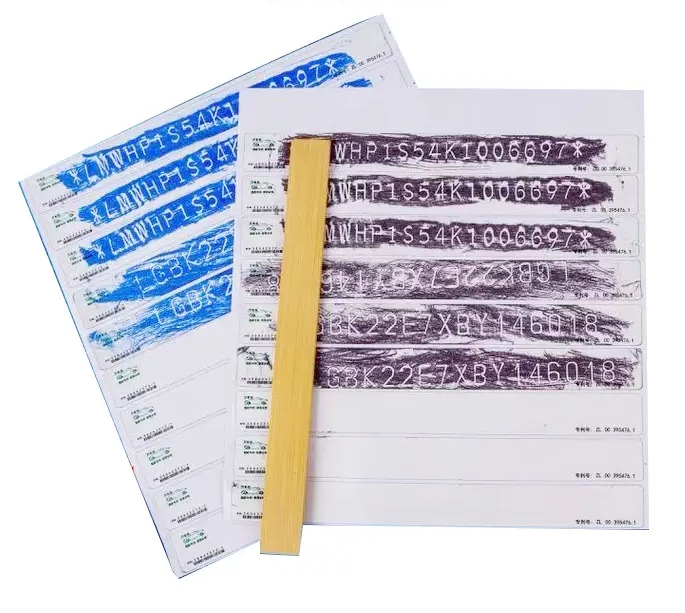

Rubbing stickers

There are two display colors for rubbing stickers: black and blue; The rubbing paper produced by our company is 100% made of high-quality materials, and the rubbing clarity is unmatched by domestic materials. With just a gentle back and forth scraping, the desired number can be clearly obtained; Printing paper that is not easily faded, resistant to high temperatures, can be stored for 15 years, and is easy to standardize management and improve efficiency

Instructions for using rubbing stickers

1. Remove the entire rubbing label and separate it from the backing paper. Then paste the rubbing label onto the object to be rubbed

2. Then use an object to scrape out the part to be printed. The object can be a bank card item. After the printing is completed, remove it as a whole

3. Then separate the main body of the stamp and the film underneath it from the left square of the stamp. The main function of this membrane is to isolate dust, and the membrane can be discarded at this time

4. Finally, paste the rubbing label onto the area to be pasted

Applied to the annual inspection of motor vehicles, registration of new cars, registration transfer, and transfer of ownership for the rubbing and archiving of vehicle engine numbers and chassis numbers. This product has the characteristics of environmental protection, anti-counterfeiting, strong adhesion, high clarity of rubbing handwriting, good durability of handwriting, and convenient and fast use. Under normal circumstances, it can be stored for 15 years

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.