Printing and processing methods for certificate labels

1. Flexographic printing method, commonly using UV ink or alcohol based ink. Before printing film materials, corona treatment should be stopped to increase the surface tension. The method of surface coating can also be used to improve the firmness of ink application. Require polishing after printing to protect the graphics and text. It is not advisable to use water-based ink to avoid the phenomenon of weak ink layer.

2. Gravure printing method, which prints on ordinary gravure printing machines (usually using wide width gravure printing machines), using solvents or UV ink. The printed labels are first divided into small rolls by a slitting machine, and then die cut, discarded, and rewound on a processing machine. Cut into individual rolls on the public slitting machine and prepare for labeling on the labeling machine.

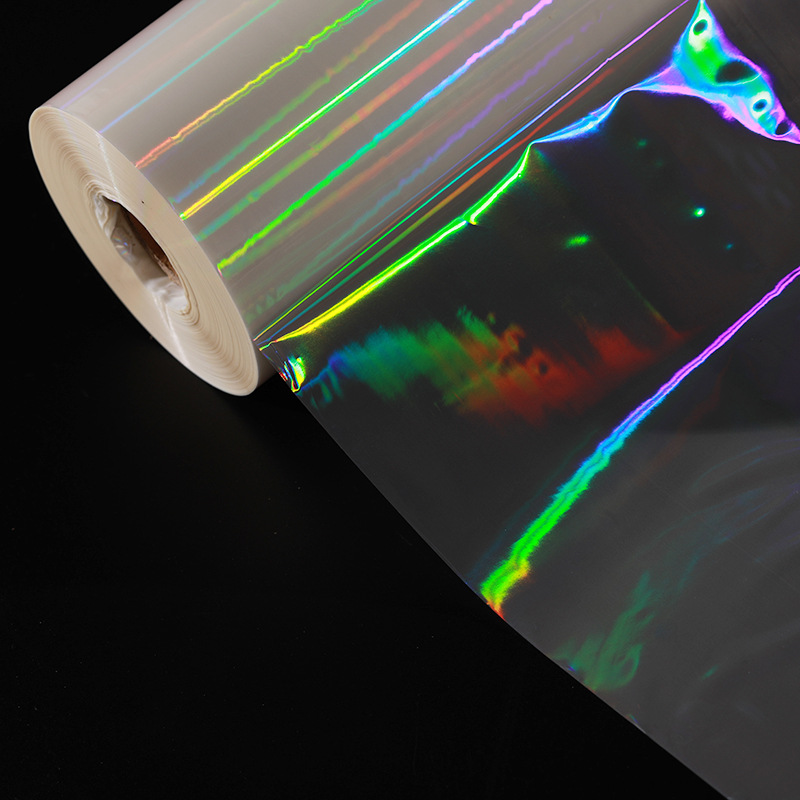

3. The gravure reverse printing method is a split printing method. Firstly, print graphics and text on the back of the public transparent PVC film using the inner printing method, and then vacuum coat the exterior of the graphics and text with aluminum to cover them. The second step is to manufacture the certificate label using printed and aluminum coated PVC film as raw material according to the adhesive material manufacturing process. Complete the entire label processing process on the label processing machine and slitting machine using the coated certificate label.

Electrostatic labeling

Craftsmanship: Cross cutting printing white

Advantages: Smooth surface with strong adhesion, can be repeatedly peeled and pasted, no glue, no traces left, can be peeled and pasted immediately, waterproof and temperature resistant, long service life, environmentally friendly and hygienic.

Disadvantages: Poor adhesion of electrostatic stickers, easy to fall off

Applicable scenarios: car window pasting (maintenance reminder and annual inspection label pasting) window grilles, etc

What is a power cord label

Power cord labels are widely used in various household appliances in our daily lives, such as rice cookers, air fryers, fans, refrigerators, electric fireplaces, lighting fixtures, hair straighteners, hair dryers, and heaters. These labels are not only product identification, but also an important manifestation of safety certification

Main Features

Corrosion resistance: able to maintain stable performance in harsh environments

Waterproof: Ensure that it is not affected in humid environments

High temperature resistance: suitable for household appliances used in high-temperature operations

Low temperature resistance: can still be used normally in low temperature environments

Adhesive folding sticker: easy to firmly stick and prevent label detachment

These features make power cord labels an essential component in various household appliances, providing assurance for product safety and information dissemination. If you have any further or special requirements for power cord labels, please feel free to contact us at any time

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.