The problem of warping when adding copperplate paper labels to daily chemical labels

Ownlikes once encountered a case where a customer reported that the label on the packaging bottle of toilet cleaner started to curl after 24 hours. At that time, the enterprise was very strange. Generally speaking, after 24 hours of labeling, the adhesive of the self-adhesive material would completely bond with the surface of the object being labeled, which should be the time when the stickiness was strongest. Why did it start to curl up 24 hours after labeling? After on-site investigation, it was found that the customer was using labels processed from copperplate paper material

We know that paper has a certain degree of water absorption, and the packaging bottles used as stickers are made of plastic material. After the packaging bottles are labeled, they are placed in the warehouse. According to tests conducted by Xingyue Printing Technology, the relative humidity in the labeling workshop was 55%, while the relative humidity in the warehouse was only 25%. The humidity in the warehouse was significantly different from that in the labeling workshop. Although plastic bottles do not shrink due to changes in humidity, the labels will shrink quickly after being placed in the warehouse due to the rapid loss of moisture, which is the reason why the labels curl up

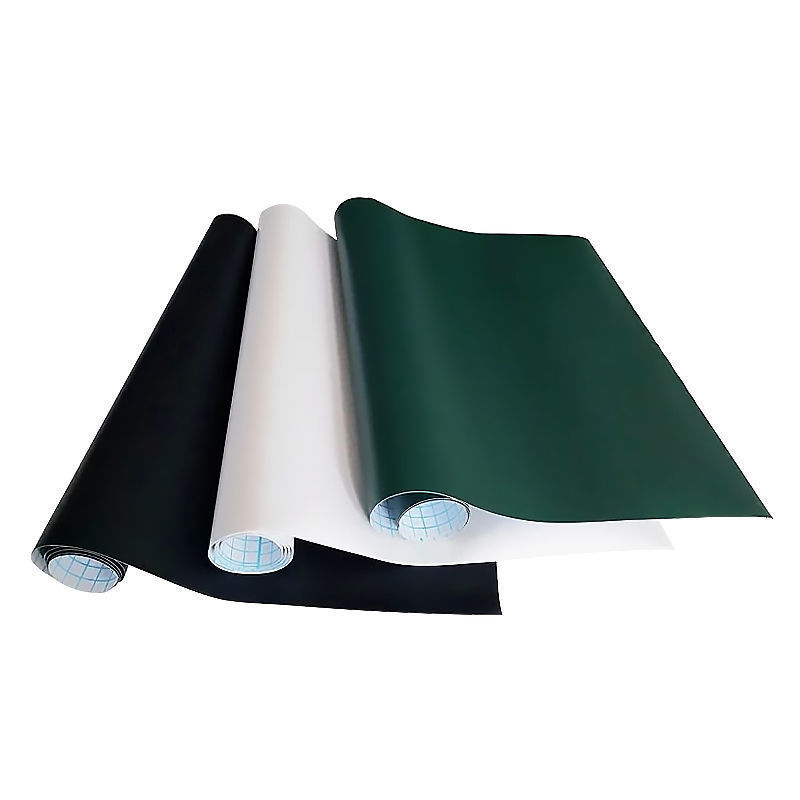

In fact, the packaging bottles of daily chemical products on the market are mainly made of high-density PE or PP materials, so using thin film adhesive labels of the same material is the most suitable: on the one hand, thin film materials are not easily affected by humidity; On the other hand, the film label made of the same material as the packaging bottle has a shrinkage rate that is basically the same as that of the packaging bottle, so it is least likely to have warping problems

However, toilet cleaner is still a relatively low-end daily chemical product. If thin film adhesive label materials are used, it will increase the product cost to a certain extent. Therefore, it is recommended that companies that must use copperplate paper to process such labels due to cost considerations must cover or polish the labels to reduce the impact of external humidity changes on the label materials

Machinery Industry Label

Precautions for Labeling in the Machinery Industry:

1. When using labels, the label paper should be kept warm (around 20 ℃) so that it can exert maximum adhesion

2. The use of labels should only be applicable in dry weather (i.e. without rain, snow, etc.)

3. Labels should be applied to concrete surfaces with temperatures above 10 ℃

4. Labels should be applied to surfaces suitable for adhesion. The surface suitable for pasting should be smooth, without cracks, holes, and gravel

5. Before pasting, the surface of the object to be pasted should be cleaned first

6. Try to avoid contaminating glue with income and expenses as much as possible

7. After pasting, it is necessary to press the label firmly a few times

Precautions for saving labels in the mechanical industry:

1. Outdoor power labels should be placed as flat as possible. Long term slanted or upright placement may cause glue overflow

2. Outdoor labels for electricity should be placed inside packaging boxes as much as possible. Placing dust and humid environments can have adverse effects on the surface of the tape and the adhesion of the adhesive

3. The retention period after opening is 1 year

4. Try to store in a dry, ventilated, and cool environment

Warning safety label

The warning safety label is made of colored vinyl as the substrate with permanent acrylic pressure-sensitive adhesive. The surface has good glossiness, durability, flexibility, and ready to stick characteristics, and can be used for printing and heat transfer printing. Its adhesive has strong adhesion properties, sticking to curved surfaces without warping, deformation, or detachment, and can withstand about 5-8 years under outdoor conditions.

Chemical safety labels

The regulations for the writing of chemical safety labels refer to the standardized and unified requirements for the labeling of the properties, hazardous characteristics, safe operation, and handling measures of chemicals. These regulations aim to ensure that chemical users have a clear understanding of the hazards and take appropriate protective measures during the use and storage of chemicals, thereby safeguarding personal safety and environmental protection.

Chemical safety is an important topic that involves personal safety and environmental protection. In daily life and work, we may come into contact with various chemicals such as cosmetics, cleaning agents, pesticides, etc. In order to ensure people's health and safety, regulations on the writing of chemical safety labels have emerged. This article aims to comprehensively introduce the relevant content of the regulations for writing chemical safety labels, so that readers can have a deeper understanding of them.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.