Heat transfer barcode paper

The lowest level in the evaluation grade of the curve parameters obtained from barcode detection (minimum edge ratio, decoding performance, stripe contrast, decoding ability, defect degree) is the grade of the curve. The levels of each parameter and the scanning reflectance curve are represented by letters A, B, CD, and F, corresponding to 4, 3, 2, 1, and 0 in the national standard, respectively. The national standard requires symbol levels not to be lower than 1.5/10/670

A-level barcode corresponds to symbol quality level: 4.0-3.5:

B-level barcode corresponds to symbol quality level: 3.4-2.5

C-level barcode corresponds to symbol quality level: 2.4-1.5:

D-level barcode corresponds to symbol quality level: 1.4-0.5

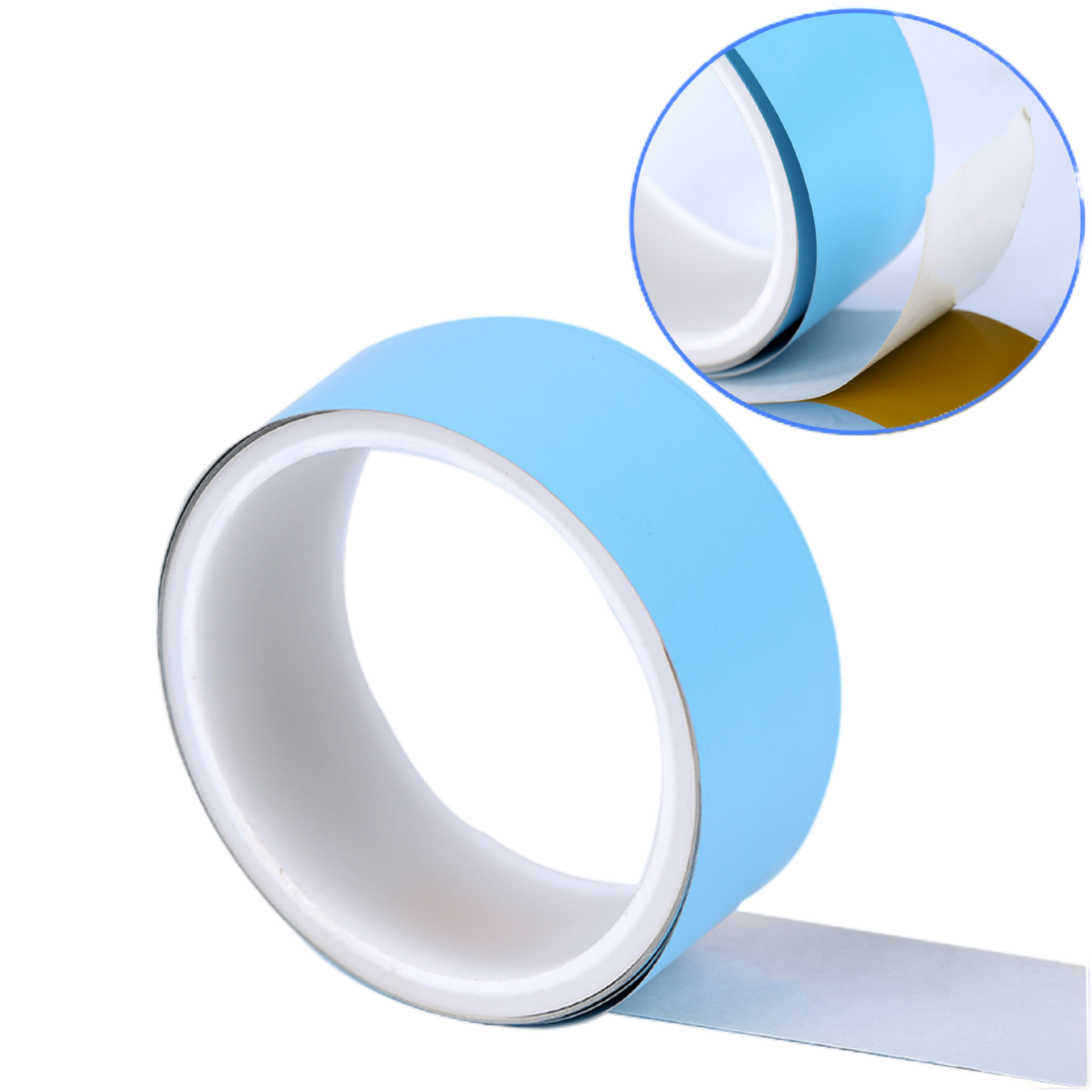

Heat transfer paper is a type of powder coated copperplate paper that has undergone special powder surface treatment and has a glossiness below 20 degrees. The paper is soft and elegant, with a matte effect, a refreshing and comfortable visual experience, and high non reflective opacity. It has excellent color saturation and vividness, and has excellent texture and ink absorption performance. It is suitable for heat transfer printing of various high-definition and high-density barcodes, and is suitable for most wax based and mixed based carbon tapes (recommended Ricoh B110A). It can easily print A-level barcodes

Heat transfer paper adhesive label

Heat transfer paper adhesive labels are a type of label made using special heat transfer technology. They combine the advantages of heat transfer printing with the convenience of adhesive labels, providing efficient, durable, and diverse identification solutions for various products.

The production process of this type of label is unique. Firstly, the pattern or text is printed on heat transfer paper using a heat transfer printing machine, and then transferred to the adhesive label through hot pressing. This manufacturing process ensures that the patterns and text on the label have extremely high clarity and durability, and even if exposed to harsh environments for a long time, the information on the label can remain clear and visible.

There are various materials for heat transfer paper adhesive labels, and suitable materials can be selected according to different application needs, such as paper, PET, PVC, etc. This enables this label to exhibit its excellent performance in various scenarios, such as water resistance, oil resistance, wear resistance, etc.

In addition, heat transfer paper adhesive labels have a wide range of application fields. It can be used in various industries and fields such as food, beverage, medicine, daily chemical, electronics, etc., providing clear labeling and anti-counterfeiting functions for products. At the same time, it can also be customized according to customer needs, such as adding QR codes, barcodes and other information, to achieve product traceability and management.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.