Steam sterilization packaging label

Steam sterilization packaging labels are indicators used to show that a product has been treated with steam sterilization. They are typically made with crepe paper or label paper as the base material, coated with color-changing ink as the sterilization indicator, and backed with pressure-sensitive adhesive. When certain sterilization conditions are met (such as 121℃ for 20 minutes or 132℃ for 3 minutes), the chemical indicator stripes on the crepe paper base will change from light yellow to black. The main function of steam sterilization packaging labels is to indicate that the product has been steam sterilized, ensuring its hygiene and safety. Additionally, steam sterilization packaging labels can also provide relevant product information, such as the production date and shelf life, helping consumers make correct choices and use the product properly.

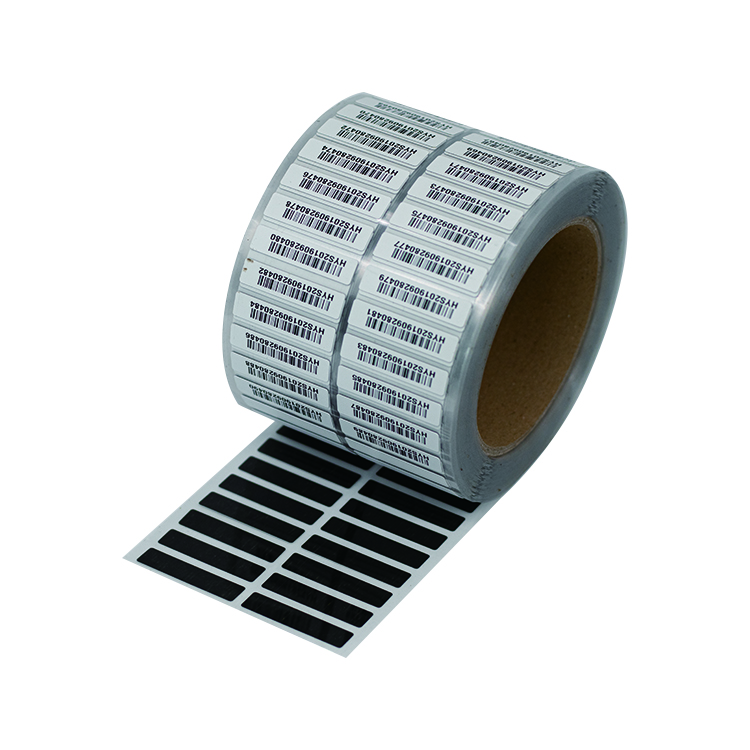

Radiation sterilization instruction label

The irradiation sterilization color-changing indicator label is a circular label with a diameter of 13mm, used as an indicator for whether irradiation sterilization products have been exposed and whether the dose has reached the required level. Compared to similar types of indicator labels, its larger diameter makes it more eye-catching and easier to identify.

Before irradiation sterilization, the yellow label is attached to the outer packaging of the product. After the irradiation dose reaches the corresponding requirement, it changes to a bright red color. The color starts to change at 4kGy, and as the dose increases, the red color gradually deepens.

There are 5000 labels per roll, and customized production is also available according to user requirements.

Requirements for sterilization labeling

The requirements for sterilization markings include the form, location, and content of the markings.

-

Form of markings: Sterilization markings typically appear in the form of graphics, text, or symbols to clearly indicate that the product has been sterilized.

-

Location of markings: Sterilization markings should be clear, easily identifiable, and placed in a visible location on the product packaging or container to ensure that consumers can easily see them.

-

Content of markings: Sterilization markings should include relevant information such as the sterilization method, date, batch number, etc., to provide information about the product's sterilization process.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.