DIN - Halogen free low smoke heat shrink cable identification tube

Designed for special requirements of cable identification for high-speed rail, subway, and urban rail multiple units, made of cross-linked environmentally friendly polyolefin heat shrink material. Meets the requirements of ASTM D 2671 B method and meets the French NFF16-101 standard. There are two types available for users to choose from: adhesive and continuous, as well as two shrinkage ratios of 2:1 and 3:1. The physical, chemical, and electrical properties such as flame retardancy, smoke density, and smoke toxicity index comply with international locomotive standards. The product printing has excellent abrasion resistance and wear resistance. Even if it is corroded by cleaning agents or military fuel before and after heat shrinkage, the color code firmness still meets the requirements of military standards SAE-AS 81531 and MIL-STD-202G/215K, maintaining a permanent identification effect. Implement standard ASTM D 2671; SAE-AS 81531;MIL-STD-202 method 215K;DIN5510-2

Features:

Heat shrink ratio: 2:1, 3:1

Initial shrinkage temperature:+ 85° C

Complete shrinkage temperature:&ge+ 125° C

Usage temperature:‐ 55° C~+125°C

Standard colors: yellow, white (other colors can be customized), high softness, light weight, flame retardant

Environmental standards: RoHS, IEC61249-2-21, EU 2002/72/EC, SS00259

Product Parameters

HMS - High Temperature Oil Resistant Identification Tube

Designed to meet the requirements for high-temperature and oil resistant cable identification, it is made of cross-linked environmentally friendly polyolefin heat shrink material. Meets the requirements of Class 1 products in military standard AMS-DTL-23053/6. There are two types available for users to choose from: adhesive and continuous, as well as two shrinkage ratios of 2:1 and 3:1. It has excellent oil resistance, especially suitable for marking wires and cables that come into contact with high-temperature hydrocarbon oils (such as JP-8 military aviation kerosene) for a long time. It is widely used in military and construction industries such as aerospace, high-speed railways, submarines and ships. The product printing has excellent abrasion resistance and wear resistance. Even if it is corroded by cleaning agents or military fuel before and after heat shrinkage, the color code firmness still meets the requirements of military standards SAE-AS81531 and MIL-STD-202F/215J, maintaining a permanent identification effect

Features:

1. High temperature resistant fuel, lubricating oil, and other organic solvents, with an oil resistance rating of up to 70 ℃× Above 168 hours

2. High temperature resistance level, rated temperature 135 ℃

3. Extremely high flame retardancy, VW-1 grade

4. Environmental performance meets the EU RoHS standard

5. Extremely high reliability, permanent identification

6. Sensitive to heat and fast to contract

7. Arbitrary printing, computer setting of characters and trademark patterns

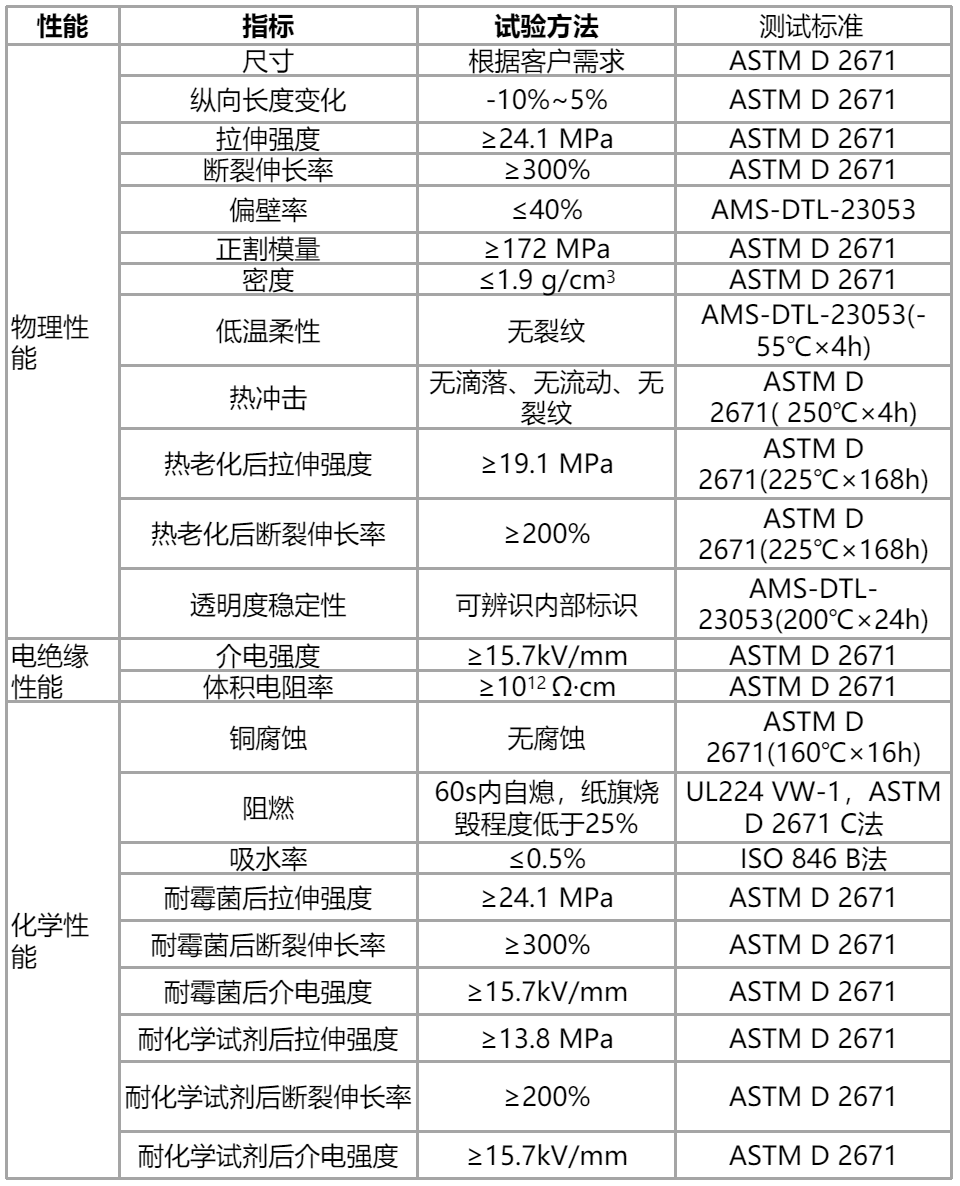

PSFR - High temperature heat shrink marking tube

Designed to meet the requirements for high-temperature and oil resistant cable identification, it is made of cross-linked environmentally friendly polyolefin heat shrink material. Meets the requirements of Class 1 products in the US military standard AMS-DTL-23053/6. There are two types available for users to choose from: adhesive and continuous, as well as two shrinkage ratios of 2:1 and 3:1. It has excellent oil resistance, especially suitable for marking wires and cables that come into contact with high-temperature hydrocarbon oils (such as JP-8 military aviation kerosene) for a long time. It is widely used in military and construction industries such as aerospace, high-speed railways, submarines and ships. The product printing has excellent abrasion resistance and wear resistance. Even if it is corroded by cleaning agents or military fuel before and after heat shrinkage, the color code firmness still meets the requirements of military standards SAE-AS 81531 and MIL-STD-202F/215J, maintaining a permanent identification effect

Product Features:

1. High temperature resistant fuel, lubricating oil, and other organic solvents, with an oil resistance rating of up to 70 ℃× Above 168 hours

2. High temperature resistance level, rated temperature 135 ℃

3. Extremely high flame retardancy, VW-1 grade

4. Environmental performance meets the EU RoHS standard

5. Extremely high reliability, permanent identification

6. Sensitive to heat and fast to contract

7. Arbitrary printing, computer setting of characters and trademark patterns

Specification and size:

How should we choose the appropriate cable label paper?

1. Cable label paper adhesion method

When selecting cable label paper, choose different adhesive methods based on the environment in which the cable label paper is used, such as roll type (flat winding type), card type, and flag type (F-type).

2. Color of cable label paper

If the wiring environment is relatively complex and there are many cables, it is best to choose cable label paper of multiple colors for classification and identification.

Many people say that pasting cable label paper is unnecessary and can remember every cable. Yes, it is possible to remember all cables in the short term, but over time, it is inevitable to forget them. Cable label paper can effectively help us reduce network configuration time, improve cable management level and maintenance efficiency. Therefore, learning to use cable label paper can really save us a lot of trouble.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.