Quotation for High-Temperature Resistant Label Barcodes

In the sticker label industry, there is a growing demand for high-temperature resistant label barcodes. These labels are specifically designed to withstand extreme temperatures, making them suitable for various industrial applications such as automotive, aerospace, and manufacturing. In this article, we will explore the importance of high-temperature resistant label barcodes and provide a comprehensive quotation for these specialized products.

Understanding High-Temperature Resistant Label Barcodes

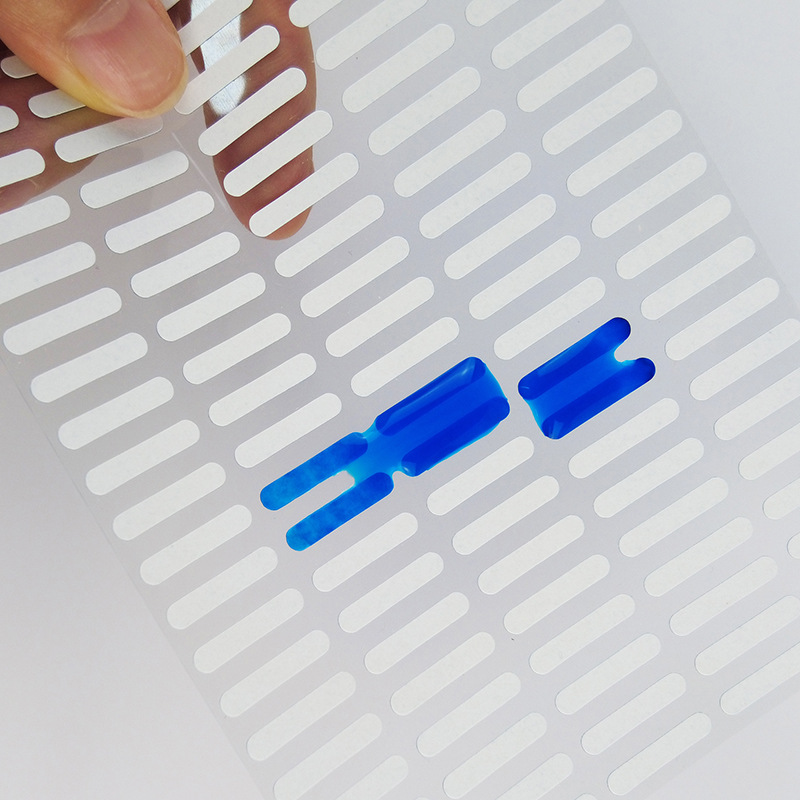

High-temperature resistant label barcodes are essential for industries that operate in extreme temperature environments. Traditional labels may not be able to withstand the heat generated during manufacturing processes or when exposed to high-temperature equipment. These labels are specifically engineered to maintain their integrity and readability even in extreme conditions.

One of the key features of high-temperature resistant label barcodes is their ability to withstand heat without smudging or fading. They are made from durable materials that can resist temperatures ranging from -40°C to 300°C, ensuring that the barcode remains scannable and readable throughout the entire process.

Additionally, these labels are designed to adhere securely to various surfaces, including metal, plastic, and glass. This ensures that the label stays in place even in high-temperature environments, preventing any loss of data or misidentification of products.

Quotation for High-Temperature Resistant Label Barcodes

When it comes to providing a quotation for high-temperature resistant label barcodes, several factors need to be considered. These factors include the material, size, quantity, and customization requirements. Here is a breakdown of the pricing structure:

1. Material: High-temperature resistant label barcodes are typically made from specialized materials such as polyester or polyimide. The choice of material depends on the specific temperature range and application requirements. The price per label varies based on the material selected.

2. Size: The size of the label is an important factor in determining the pricing. Larger labels require more material and may involve additional processing steps. The price per label increases with the size.

3. Quantity: The quantity of labels needed also affects the pricing. Bulk orders often receive discounted rates due to economies of scale. The price per label decreases as the quantity increases.

4. Customization: If customization is required, such as adding company logos, serial numbers, or barcodes, additional charges may apply. The complexity and number of customizations influence the overall price.

It is important to note that the quotation provided is subject to change based on specific customer requirements and any additional services requested, such as label printing or application assistance.

Conclusion

High-temperature resistant label barcodes play a crucial role in industries that operate in extreme temperature environments. These labels ensure the integrity and readability of barcodes, even in the harshest conditions. When requesting a quotation for high-temperature resistant label barcodes, factors such as material, size, quantity, and customization requirements need to be considered. By understanding these factors, businesses can make informed decisions and choose the most suitable labels for their specific needs.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.