Color Options for High-Temperature Labels: Colored or Black?

Introduction:

High-temperature labels play a crucial role in various industries where extreme heat is a constant challenge. These labels are designed to withstand elevated temperatures without compromising their readability and adhesive properties. One critical consideration when choosing high-temperature labels is the color option. This article explores the advantages and disadvantages of colored and black labels in high-temperature environments.Colored Labels:

Colored labels offer several benefits when it comes to high-temperature applications. Here are some key points to consider:

1. Enhanced Visibility:

Colored labels are ideal for applications where visual identification is crucial. The use of vibrant colors allows for quick and easy identification of specific items or equipment, even in high-temperature environments.2. Improved Safety:

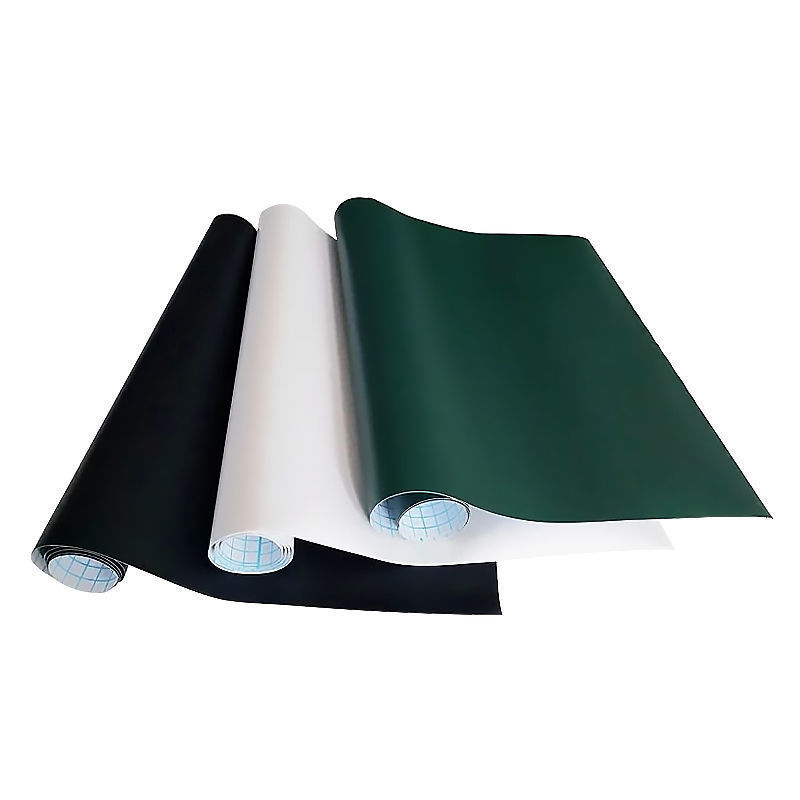

In industries where safety is a top priority, colored labels can be used to indicate potential hazards or safety precautions. For example, red labels can signify areas with extreme heat, yellow labels can indicate caution, and green labels can represent safe zones.3. Customization Options:

Colored labels offer a wide range of customization options, allowing businesses to match the labels with their branding or specific requirements. This level of customization can enhance the overall aesthetic appeal of the labeled items.4. Differentiation:

Using colored labels can help differentiate between various components or equipment, making it easier to identify specific items in a high-temperature environment. This can streamline processes and reduce errors.Black Labels:

While colored labels have their advantages, black labels also offer unique benefits in high-temperature settings. Let's explore some key points:

1. Heat Absorption:

Black labels have the advantage of absorbing heat more efficiently compared to colored labels. This characteristic can be beneficial in certain applications where heat dissipation needs to be minimized, preventing potential damage to the label or the adhesive.2. Minimal Reflection:

Black labels have a low reflectivity level, which can be advantageous in environments where excessive glare or reflection may hinder visibility. This is particularly important in industries where accurate reading of information is critical.3. Professional Appearance:

Black labels are often associated with a professional and sleek appearance. This can be beneficial in industries that prioritize a clean and sophisticated aesthetic, such as automotive, aerospace, or high-end consumer electronics.4. Universal Compatibility:

Black labels can be universally compatible with various color schemes and backgrounds. This versatility ensures that the labels can be easily integrated into existing systems or designs without clashing with other colors or patterns.Conclusion:

When it comes to choosing color options for high-temperature labels, both colored and black labels offer unique advantages. Colored labels provide enhanced visibility, improved safety, customization options, and differentiation. On the other hand, black labels excel in heat absorption, minimal reflection, professional appearance, and universal compatibility. The choice ultimately depends on the specific requirements of the industry and the intended application. By carefully considering these factors, businesses can select the most suitable color option for their high-temperature labels, ensuring optimal performance and readability in challenging environments.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.