Essential Materials for Heat Resistant Labels

Heat resistant labels play a crucial role in various industries, ensuring that important information remains intact even in high-temperature environments. These labels are designed to withstand extreme heat, making them suitable for applications such as automotive, electronics, and industrial manufacturing. To achieve the desired level of durability and functionality, specific materials are essential for the production of heat resistant labels. In this article, we will explore the key materials used in the sticker label industry for heat resistant applications.

1. Substrates

The substrate is the base material on which the label is printed. In the case of heat resistant labels, the substrate needs to withstand high temperatures without warping or degrading. Common substrates used for heat resistant labels include polyester (PET) and polyimide (PI). These materials have excellent thermal stability and can endure extreme temperatures without losing their structural integrity. Additionally, they provide good chemical resistance, ensuring that the labels remain intact in harsh environments.

2. Adhesives

Adhesives are crucial for ensuring that the label adheres firmly to the desired surface. In heat resistant labels, special adhesives are used to withstand high temperatures without melting or losing their bonding properties. Silicone-based adhesives are commonly employed due to their exceptional heat resistance. These adhesives can withstand temperatures up to 300°C (572°F) without compromising the label's adhesion. Furthermore, silicone adhesives offer excellent chemical resistance and can adhere well to various substrates, including metal, glass, and plastics.

3. Inks

Inks used for heat resistant labels must be able to withstand high temperatures without fading, smudging, or losing legibility. Thermal transfer inks are commonly used due to their excellent resistance to heat. These inks are designed to withstand temperatures up to 300°C (572°F) and maintain their color and clarity. Additionally, thermal transfer inks offer good chemical resistance, ensuring that the labels remain readable even in harsh environments.

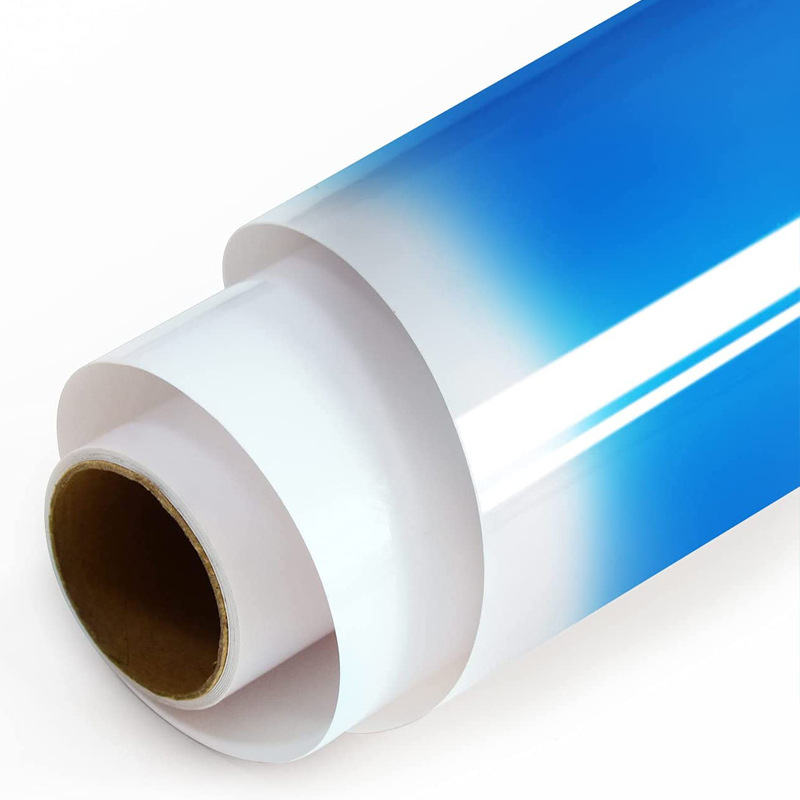

4. Overlaminates

Overlaminates provide an extra layer of protection to heat resistant labels, enhancing their durability and resistance to heat, chemicals, and abrasion. Polyester (PET) overlaminates are widely used in the sticker label industry due to their excellent thermal stability and resistance to high temperatures. These overlaminates not only protect the label from heat but also provide a smooth finish and enhance its overall appearance.

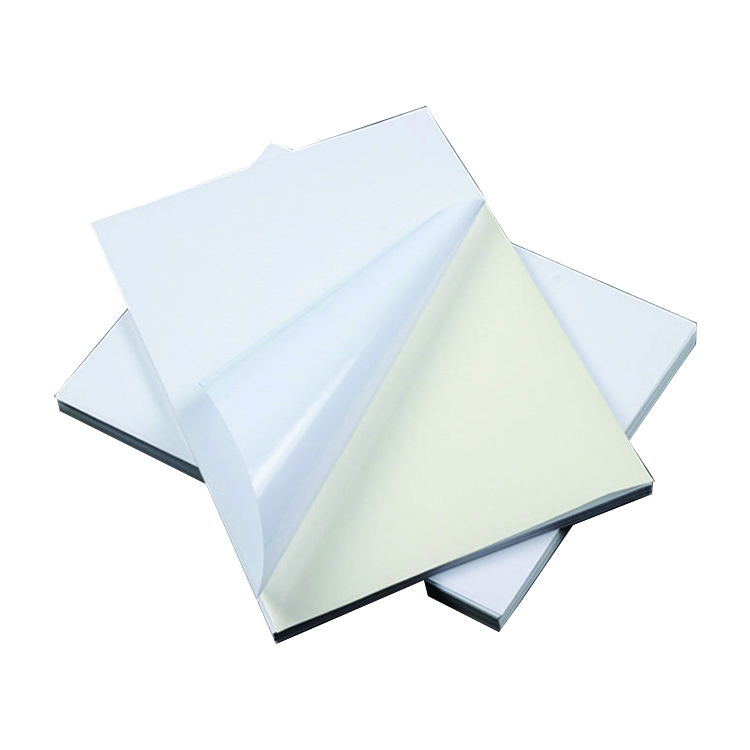

5. Release Liners

Release liners are essential components of heat resistant labels, serving as the backing material that protects the adhesive until the label is ready for application. For heat resistant labels, release liners made from materials such as polycoated paper or polyester film are commonly used. These liners offer excellent dimensional stability and can withstand high temperatures during the label application process.

In conclusion, the production of heat resistant labels requires specific materials that can withstand extreme temperatures, chemicals, and harsh environments. Polyester and polyimide substrates, silicone-based adhesives, thermal transfer inks, polyester overlaminates, and release liners made from polycoated paper or polyester film are essential components in the sticker label industry for heat resistant applications. By using these materials, manufacturers can ensure that their heat resistant labels maintain their integrity and legibility, even in the most demanding conditions.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.