Superior Heat-Resistant Label Materials: A Must-Have for Enduring High Temperatures

In the world of sticker label manufacturing, the ability to withstand high temperatures is a crucial factor for many industries. From automotive to aerospace, electronics to industrial applications, the need for heat-resistant labels is paramount. These labels not only provide important information but also ensure the durability and longevity of the products they adorn. In this article, we will explore the significance of superior heat-resistant label materials and their importance in enduring extreme temperatures.

The Challenges of High Temperatures

High temperatures pose significant challenges for labels. Ordinary labels, when exposed to extreme heat, can warp, fade, or even melt, rendering them illegible and ineffective. In industries where temperature fluctuations are common, such as automotive or industrial manufacturing, labels need to withstand not only high temperatures but also rapid temperature changes. Furthermore, labels must remain intact and readable even in harsh environments with exposure to chemicals, solvents, and UV radiation.

The Role of Superior Heat-Resistant Label Materials

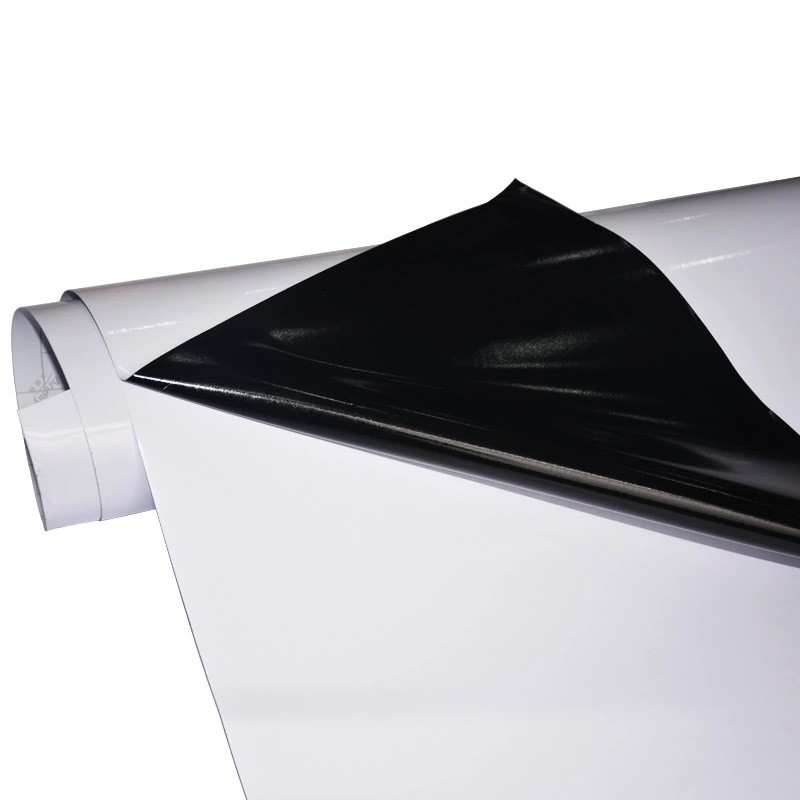

Superior heat-resistant label materials are specially designed to overcome the challenges posed by high temperatures. These materials are engineered to withstand extreme heat without compromising their integrity or legibility. They are made from durable substrates that can resist warping, melting, or fading, ensuring that the label remains intact and readable in even the harshest conditions.

One of the key components of heat-resistant label materials is the adhesive. Conventional adhesives may lose their grip or even disintegrate under high temperatures. However, superior heat-resistant label materials utilize advanced adhesive technologies that can withstand extreme heat without losing their adhesive properties. These adhesives are formulated to maintain their bond strength, ensuring that the label remains securely attached to the product throughout its lifecycle.

Applications of Heat-Resistant Labels

The applications of heat-resistant labels are vast and varied. In the automotive industry, these labels are used on engine components, exhaust systems, and other parts that are exposed to high temperatures. They provide crucial information about maintenance, safety precautions, and part identification, ensuring that the right actions are taken to prevent any potential risks or failures.

In the aerospace industry, heat-resistant labels are used on aircraft engines, turbines, and other critical components. These labels withstand the extreme temperatures generated during flight and ensure that the necessary maintenance and safety procedures are followed. They also help in tracking and identifying parts for efficient maintenance and replacement.

Heat-resistant labels are also vital in the electronics industry, where they are used on circuit boards, power supplies, and other electronic components. These labels can endure the high temperatures generated during soldering and other manufacturing processes without losing their legibility or adhesive properties. They provide essential information about component specifications, assembly instructions, and safety warnings.

Conclusion

In conclusion, superior heat-resistant label materials play a crucial role in various industries where high temperatures are a constant challenge. These labels withstand extreme heat, rapid temperature changes, and harsh environments while remaining intact and readable. With their advanced adhesive technologies and durable substrates, heat-resistant labels ensure that important information is conveyed accurately, maintenance procedures are followed, and safety precautions are taken. Investing in superior heat-resistant label materials is a must-have for industries that strive for durability, reliability, and longevity even in the face of extreme temperatures.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.