High-Temperature Resistant Label Manufacturers: Ensuring Quality and Durability

The sticker label industry plays a crucial role in various sectors, from consumer products to industrial applications. One specific niche within this industry is high-temperature resistant label manufacturing. These labels are engineered to withstand extreme heat and harsh conditions, making them essential for industries such as automotive, aerospace, electronics, and more. In this article, we will delve into the intricacies of high-temperature resistant label manufacturing, highlighting its importance, manufacturing process, and key applications.

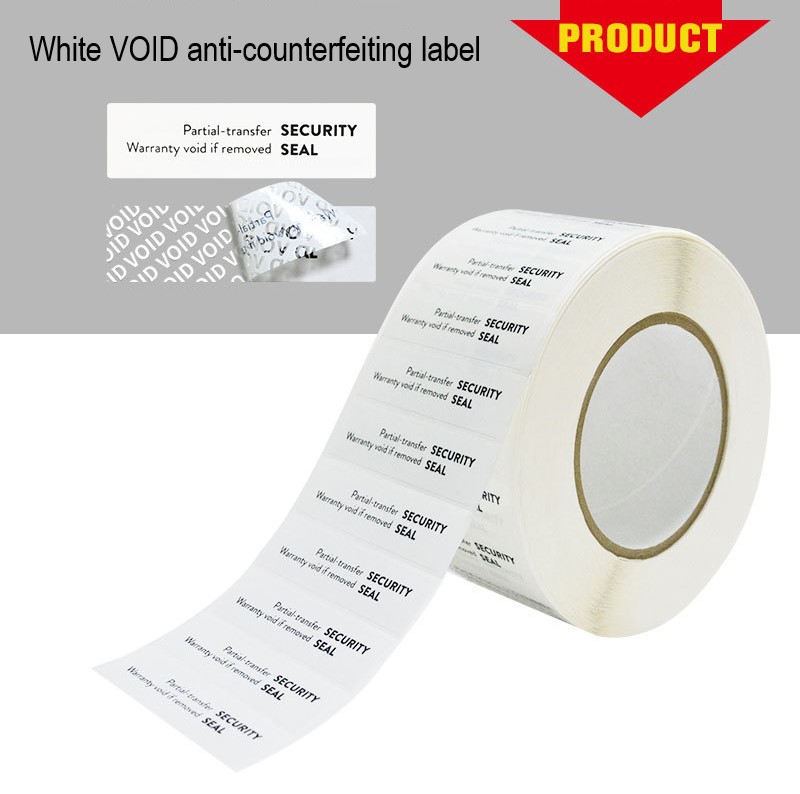

The Significance of High-Temperature Resistant Labels

High-temperature resistant labels are a vital component in industries where exposure to extreme heat is a daily challenge. These labels are designed to endure temperatures far beyond the capability of standard labels, making them indispensable in various applications. Whether it's an automotive engine, aerospace equipment, or electronic devices, high-temperature resistant labels ensure that critical information remains intact even in the harshest environments.

Manufacturing Process

The production of high-temperature resistant labels is a precise and sophisticated process that requires specialized materials and techniques. The following steps provide an overview of how these labels are manufactured:

1. Material Selection

The foundation of any high-temperature resistant label is the choice of materials. Manufacturers select materials that can withstand elevated temperatures, such as polyester, polyimide, or ceramic-based substrates. These materials offer exceptional thermal stability, ensuring that the label remains intact even when exposed to extreme heat.

2. Printing

The printing process for high-temperature resistant labels involves using high-quality inks and printing technologies that can withstand heat. Common printing methods include thermal transfer printing, screen printing, or laser marking. These methods ensure that the labels' content remains legible even under extreme conditions.

3. Adhesive Application

High-temperature labels require adhesives that can maintain their bonding strength at elevated temperatures. Manufacturers use specially formulated adhesives that are resistant to heat and can adhere to various surfaces, including metals, plastics, and ceramics.

4. Cutting and Shaping

Once the label material has been printed and adhesive applied, the labels are cut and shaped to the desired dimensions. Precision cutting is crucial to ensure that the labels fit the specific requirements of the application.

5. Quality Control

Quality control is a fundamental step in the manufacturing process. Labels are inspected for print quality, adhesion strength, and overall durability. Any labels that do not meet the stringent standards are rejected to ensure only the highest-quality products reach the market.

Applications of High-Temperature Resistant Labels

The versatility of high-temperature resistant labels makes them invaluable in a wide range of industries. Some key applications include:

1. Automotive Industry

High-temperature labels are commonly used in the automotive sector for labeling engine components, exhaust systems, and brake parts. These labels provide critical information that must remain legible even in the presence of extreme heat and mechanical stress.

2. Aerospace and Aviation

In the aerospace and aviation industry, high-temperature resistant labels are used on aircraft components, engines, and landing gear. These labels ensure that maintenance instructions, serial numbers, and safety information remain visible and intact under extreme conditions.

3. Electronics and Semiconductors

Electronics and semiconductor manufacturing rely on high-temperature labels to mark components, circuit boards, and chips. These labels are essential for tracking and quality control in the production process, even in high-temperature reflow soldering operations.

4. Oil and Gas Sector

High-temperature labels play a crucial role in the oil and gas industry, where equipment is subjected to high temperatures and corrosive environments. These labels are used on pipelines, valves, and storage tanks to provide essential information and ensure safety standards are met.

5. Research and Development

In research and development, high-temperature labels are utilized in laboratories and test environments where extreme temperatures are intentionally generated. These labels help researchers identify and monitor samples and equipment during experiments.

Conclusion

In the world of label manufacturing, high-temperature resistant labels stand as a testament to innovation and precision. These labels are engineered to endure the harshest conditions, ensuring that crucial information remains intact and visible. From the automotive industry to aerospace, electronics, and beyond, the applications of high-temperature resistant labels are both diverse and indispensable. Through careful material selection, printing, and quality control, high-temperature resistant label manufacturers continue to meet the demands of industries that rely on durability and reliability in the face of extreme heat.

For more information on high-temperature resistant labels and their applications, please reach out to our experienced team of professionals at [Your Company Name].

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.