Conducting Thermal Sensitivity Tests in the Sticker Label Industry

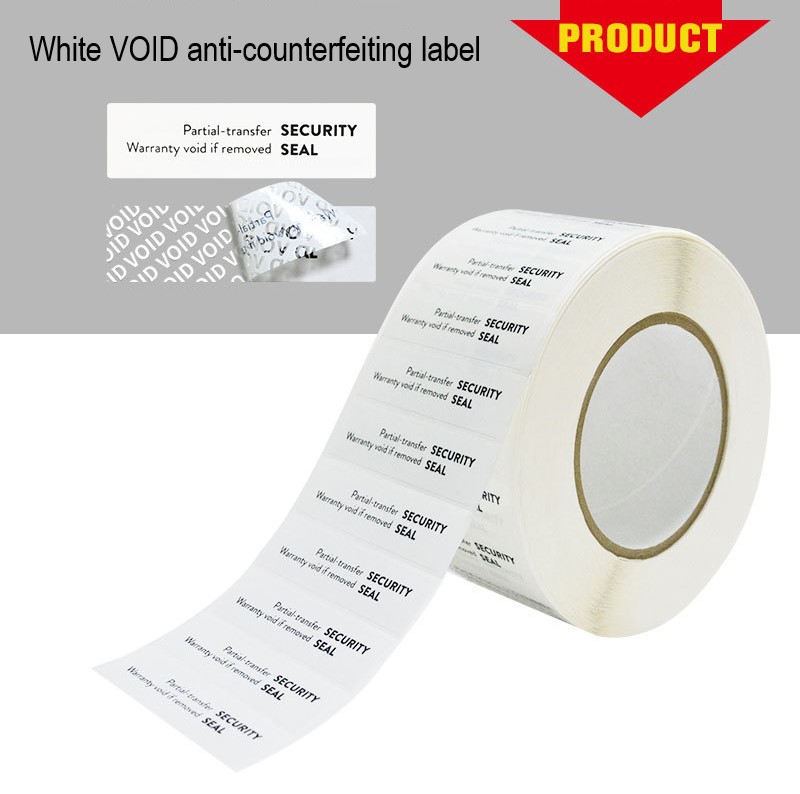

In the sticker label industry, ensuring the quality and performance of products is of utmost importance. One critical aspect is the thermal sensitivity of sticker labels, as it directly impacts their adhesive properties and overall functionality. This article will guide you through the process of conducting thermal sensitivity tests to maintain the highest industry standards.

Understanding Thermal Sensitivity

Thermal sensitivity refers to how sticker labels respond to changes in temperature. This property is crucial because labels often need to adhere to various surfaces under different environmental conditions. The industry standard for thermal sensitivity testing is ASTM D2979.

Equipment and Materials

The following equipment and materials are required for conducting thermal sensitivity tests:

- Sticker labels

- Oven

- Thermocouples

- Data acquisition system

- Environmental chamber

- Calibrated thermometer

Testing Procedure

The thermal sensitivity test should be performed as follows:

- Prepare the sticker labels for testing.

- Place thermocouples on the label's surface to monitor temperature changes.

- Place the labeled sample in the environmental chamber.

- Set the temperature and humidity conditions as specified in ASTM D2979.

- Initiate the test and record temperature and time data with the data acquisition system.

- After the specified duration, remove the sample and evaluate the label's condition.

- Repeat the test for various temperature and humidity conditions if needed.

Interpreting Results

The test results are crucial in determining a sticker label's thermal sensitivity. The adhesive properties of a label can change under different temperature conditions, affecting its performance. The following factors should be considered when interpreting results:

- The label's adhesive strength at different temperature points.

- Any visible changes in the label's appearance or texture.

- The label's ability to maintain its adhesion over time in varying conditions.

- The impact of humidity on label performance.

Quality Control and Improvement

Conducting thermal sensitivity tests is a critical step in quality control for the sticker label industry. It helps identify potential issues with labels under varying temperature conditions. Based on the results, necessary adjustments can be made to improve label quality and performance.

Conclusion

Ensuring the thermal sensitivity of sticker labels is vital to meet industry standards and customer expectations. Following the ASTM D2979 procedure and interpreting the results accurately can lead to higher-quality sticker labels that perform consistently under different environmental conditions.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.