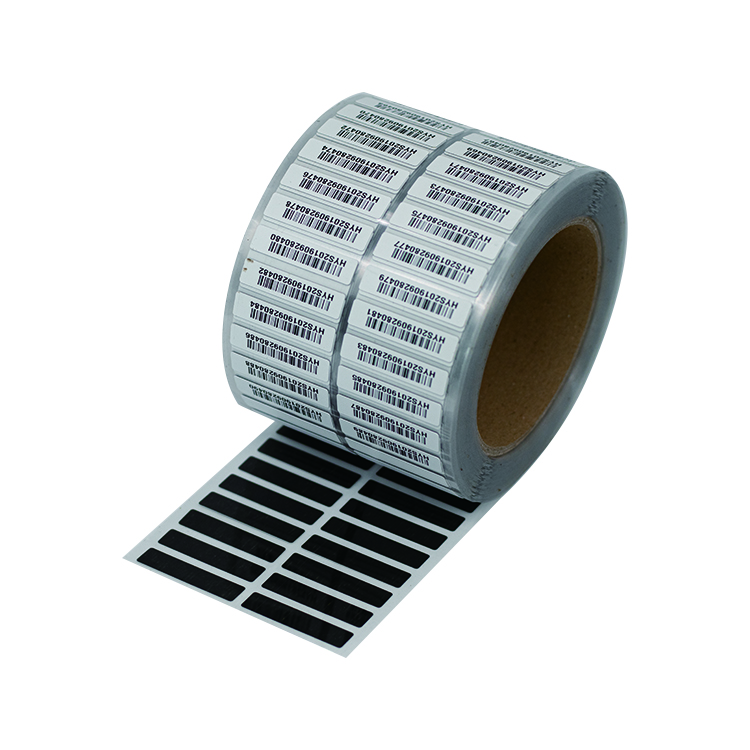

Adhesive label die-cutting overflow glue

Die cutting overflow refers to the overflow of adhesive at the edge of the label after processing through the label die cutting process. It is a common defect in adhesive products. Adhesive overflow can cause issues such as label appearance defects, printing contamination, and poor peeling. The problem of overflow glue in die-cutting can also be solved from the following aspects:

1. Performance analysis of label materials: Different types of materials have different adhesive types, adhesive processing properties, and other characteristics. Therefore, before production, you should consult with the material supplier about the relevant performance characteristics and choose the material that is suitable for your processing technology

2. Label processing and storage environment control: The temperature of the label processing and storage environment should be controlled within the range of 23+/-3 degrees Celsius, and the humidity should be controlled within the relative range of 55+/-5%. Excessive temperature and humidity will increase the fluidity of the adhesive. In actual production, we can clearly feel that during summer production, die cutting overflow is more common, while in winter it is rare, which is the same principle

3. Quality control of label die-cutting: Sharp cutting tools must be used to die cut the labels. Blunt edged blades will cause the adhesive on the labels to flip and squeeze, resulting in adhesive overflow at the edges of the labels during the die-cutting process. Excessive die-cutting pressure can also cause excessive compression of the label adhesive, while shallow die-cutting pressure may lead to wire drawing of the adhesive during the die-cutting process, resulting in adhesive overflow at the edge or surface of the label. Therefore, the choice of die-cutting knife is crucial

4. Label processing technology control: It is necessary to avoid sliding friction on the label during the label processing process. Components that have sliding friction with the label are prone to accumulating die-cutting adhesive, which can contaminate the edge of the label. This overflow phenomenon will show a clear pattern and directionality in the position of the label

5. Label rewinding tension control: Excessive rewinding tension can cause excessive compression of the label adhesive, and even cause the label to slip on the backing paper, resulting in label overflow. Non square shaped labels, due to the inconsistent axial tension of the rewinding, are prone to excessive local tension, resulting in local adhesive overflow of the label. Small square labels are also prone to label overflow due to their ability to withstand greater pressure under the same pressure

Adhesive label die-cutting bottom paper cutting through

On many manually labeled products, the phenomenon of cutting through the bottom paper by die-cutting is very common, mainly due to the limitations of the precision of the customer's die-cutting device and the requirement of no tension on the bottom paper by the labeling method;

If it is automatic labeling, cutting through the die-cutting base paper often leads to the end user encountering label base paper breakage during automatic labeling. Therefore, we should choose the roller cutting method with higher die-cutting accuracy.

adhesive labels still play an important role in enterprise management and anti-counterfeiting measures against counterfeit goods

1. Improve production management efficiency: Through QR code adhesive labels, companies can quickly obtain relevant information about products, including production progress, inventory status, etc. This helps companies to better plan and manage production

2. Anti counterfeiting and anti smuggling: QR code adhesive labels can help consumers distinguish between genuine and fake products, preventing the circulation of counterfeit and inferior products. Consumers only need to scan the QR code to verify the authenticity of the product and ensure the purchase of genuine products

3. Improving the quality of after-sales service: QR code adhesive labels can be associated with after-sales service information, and consumers can scan the QR code to obtain after-sales service contact information, warranty period, and other information, improving the quality and efficiency of after-sales service

QR code adhesive labels, as an intelligent choice, meet the needs of product traceability and play an important role in enterprise management and anti-counterfeiting measures. By implementing product traceability, consumers can purchase products with greater peace of mind, and businesses can also improve their brand image and supply chain management level. The intelligent application of QR code adhesive labels provides more business opportunities and competitive advantages for enterprises, which is worth further exploration and application

Red wine adhesive label material

1. Visual impact

Placed on the same shelf as many other alcoholic products, your alcohol label will be clear at a glance. With long-term experience in the wine and spirits market, Ownlikes provides us with a professional design team that works closely with label designers, ensuring they have a variety of platforms and product choices to launch the best and most eye-catching brand image. The Ownlikes series of wine and spirits bottle label product combinations offer different traditional, modern, and special paper and film options. Natural wine label paper based on texture responds to environmental consumer demand, and responds to fashion consumer demand with gorgeous gold labels

2. Functional Performance

Ownlikes' product design achieves functionality in an elegant form. They address perennial challenges such as peeling, edge lifting, wrinkles, and slippage, as well as risks associated with temperature changes during transportation, storage, and use. As a pioneer in the self-adhesive industry, Ownlikes continuously improves its materials and adhesives to ensure that our solutions are suitable for their respective applications and can face the future

Types of Printing Ink for Adhesive Labels

In the modern printing industry, the application of self-adhesive labels is becoming increasingly widespread, and different types of printing inks have a significant impact on the quality and effectiveness of self-adhesive labels. This article will provide a detailed introduction to several common types of adhesive label printing inks

Introduction to Ink Types for Adhesive Label Printing

1. Solvent based ink: Solvent based ink is a common printing ink, mainly composed of pigments, resins, and organic solvents. Its advantages are fast drying, strong adaptability to printing materials, and suitability for high-speed printing. However, due to the use of organic solvents, the environmental performance is poor

2. Water based ink: Water based ink is an environmentally friendly ink that uses water as the solvent, pigments, and dispersants as the main components. Its advantages are low toxicity, odorless, non flammable, and meet environmental requirements, making it the preferred choice for adhesive label printing. But its drying time is long and it requires high requirements for printing equipment

3. Ultraviolet (UV) cured ink: UV ink is a new type of ink, and its curing process involves a chemical reaction of the photoinitiator in the ink through UV irradiation, resulting in rapid curing. The advantages of UV ink are fast drying speed, good printing effect, bright colors, and minimal environmental pollution. However, the investment cost of ultraviolet equipment is relatively high

4. Thermosetting ink: Thermosetting ink is an ink that solidifies through heating and is suitable for use in high-temperature environments. Its advantages are high temperature resistance, stable printing effect, but longer drying time

5. Stereoscopic ink: Stereoscopic ink can create raised graphics and text during the printing process, giving labels a three-dimensional effect. This type of ink can provide better visual and tactile effects for adhesive labels, making it suitable for printing high-end product labels

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.