Reasons for causing the edge of self-adhesive labels to curl up

I believe that after staying in this industry for a long time, we often see some self-adhesive labels with raised edges after a period of use. What is going on

The key factors causing the edge of self-adhesive labels to curl up are as follows:

1. Adhesive viscosity is weak:

Suitable adhesive raw materials should be selected based on the object being pasted

2. Insufficient working pressure of the pressure roller of the labeling machine:

Adjust the working pressure of the pressure roller

3. The quality or type of label surface material does not comply with regulations:

When selecting label materials, consideration should be given to whether the labeled object is horizontal or inclined, large or small diameter, single inclined or curved, rigid or compressible. These indicators are directly related to the selection of the material. The soft plastic bottle body should be made of soft adhesive materials such as PE, PVC, non stretched PP and other composite materials, while the hard bottle body can be made of PET or BOPP materials

4. Unreasonable selection of adhesive:

When selecting adhesive for self-adhesive labels, the first thing to clarify is whether the adhesive required for the manufactured self-adhesive labels is permanent or removable, whether it is one-time adhesive or re adhesive, and whether the product has special requirements for the organic chemical characteristics of the adhesive for self-adhesive labels. For example, when labeling on surfaces with large curvature (circular plates with a diameter less than 2cm), thick or hard paper materials (such as mirror glass copperplate paper) are not suitable for the surface material. Instead, plastic film or thin soft paper materials with high original adhesive should be used; For vessels that require hot filling, it is advisable to use thin film materials and adhesives with good original viscosity for adhesive printing surface materials

5. Poor control of film tension:

After being properly coated, the label can be peeled off from the base paper and leveled without rolling, and the label can maintain good followability after labeling. After the label with too tight film tension is peeled off from the backing paper, the label will curl up, which can easily cause the edge of the label to peel off and curl up after labeling

6. The design scheme of the bottle body shape is not scientific:

An effective formulation should be a flat surface within the scope of bottle labeling (the key is in the design scheme of the flat round bottle body). If the surface within the labeling scope is partially spherical, the total area will be large when using paper labeling, and it is very easy for wrinkles to appear on both sides after labeling

What are the specific ways in which self-adhesive labels can be processed?

Adhesive labels, as an important component of product packaging, have functions such as advertising promotion and product instructions. They are an important way to identify and distinguish products, and play an important role in reflecting product quality and causing consumer purchases. Different varieties of raw materials and labels with different uses also use different processing techniques

The general label printing machine is a multi-purpose machine equipment, and the manufacturer can formulate the printing production process according to the needs. The production process of adhesive label printing and processing is as follows:

1) Unwinding

Intermittent type: There is no tension change when unwinding the roll paper, so there is no need to adjust it. Used in flat and round flat label machines, the unwinding speed is relatively slow. Because these types of machines and equipment do not have precise positioning and calibration devices for printing paper, it is required that the inner holes of the roll paper be clean and tidy to ensure accurate printing during printing

B Rotary type: used in the wheel transformation circular pressing circular label machine. Because when the diameter rate of the roll paper changes, the tension of the paper changes, this equipment has a fully automatic or manual tension adjustment mechanism, as well as a roll paper correction device calibration equipment to ensure stable paper feeding and printing quality

2) Hot stamping

Flattening: Used in circular flattening and flattening label machines, with low speed

Round press: Used in round press label printing machines, it has a faster speed and can continuously heat gold letters. It is generally rarely used and is widely replaced by gold stamping processing technology

3) Printing

Flattening: Suitable for printing small areas and simple patterns, such as labels, barcodes, etc

Round flattening: Suitable for label printing with solid, general patterns, and can achieve simple colorful tone printing

Round pressing: Suitable for printing various pattern labels, especially for printing high-end colorful and tonal labels

UV printing: In the above three printing methods, combined with UV drying, thin film adhesive materials can be printed

4) Hot stamping first, then printing

On facilities without UV drying, the use of general ink has the drawback of limited printing design patterns

5) Print first, then hot stamping

Applied to facilities with UV drying devices, the ink is quickly dried and then hot pressed onto the ink. The hot stamping pattern can be freely designed without being limited by the ink, making it suitable for printing high-end labels and a modern production process

6) Polishing

On site polishing: Apply a layer of varnish on the surface of the ink to maintain the ink layer, waterproof, moisture-proof, and enhance the surface glossiness. It can replace the laminating process and use UV drying method

7) Coating

The purpose of laminating on paper or film raw materials is to maintain ink, moisture and water resistance, enhance the strength of labels, and improve the layering of patterns. Lamination can be divided into two types: backing paper lamination and non backing paper lamination, as the latter is low-cost and widely used at present. According to the standards of processing technology, there are two types: composite transparent film and matte film, with the former being more widely used

8) Punching

Not widely used, but mainly suitable for labels printed by electronic computers. The regulation is to drill precise positioning and pushing holes on both sides of the label, or for the label used on the pricing gun, it is stipulated to drill a hole in the center of the label for precise positioning and pushing

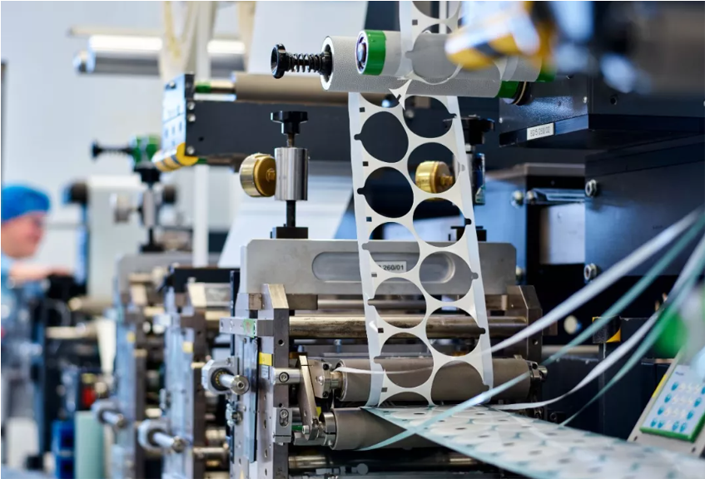

9) Die cutting

The die-cutting of adhesive labels is a semi cutting process, which only cuts through the surface raw material and preserves the base paper. Divided into two production and processing methods:

Like flat die cutting, suitable for various label printing machines, manual printing and plate making, low cost, short printing and plate making cycle time, but low viscosity, suitable for short form printing and production processing. At present, almost all label factories in China use the flat die cutting method

In addition, there is a circular die-cutting method, which is used on equipment with circular label pressing machines. It has faster speed, high die-cutting viscosity, and is suitable for long plate making. The disadvantage is that printing and plate making costs are high and take a long time. At present, the die-cutting rollers of Chinese manufacturers are generally produced and processed overseas

10) Paper delivery

It can be roughly divided into sheet cutting and folding paper delivery

How should film stickers be stored?

Previously, I shared with you the elements of seasonal storage for adhesive materials. But there are many types of adhesive materials, among which thin film adhesive materials are a common and diverse type of material. Today, let's take a look at how to store this type of adhesive material together

From the appearance, the structure of thin film adhesive materials consists of three parts: surface material, adhesive, and base paper. Among them, the substrate and adhesive are the primary factors affecting the material properties. Therefore, the maintenance and use of thin film adhesive materials should start from these two areas

1. Temperature and humidity control is important

The vast majority of thin film adhesive materials have looser requirements for natural environmental temperature and humidity compared to paper adhesive materials. PE, PP, PET, and PVC films have high water resistance and oil resistance, and have little response to temperature changes. Special attention must be paid to the fact that thin film adhesive materials have a lower absorption capacity for adhesives than paper adhesive materials. Therefore, hot-melt sol thin film adhesive materials are not easy to store under high temperature conditions, otherwise it is easy to cause adhesive leakage. If there is a glue leakage situation, it is best to carry out powder wiping or edge cutting before application, otherwise it is easy for the adhesive to overflow after machine operation, and in severe cases, it will continue to stick to the roller

Different adhesives require different storage conditions for thin film adhesive materials. Thin film adhesive materials often use permanent hot melt adhesives. Due to the high viscosity of hot melt adhesives, they are not suitable for storage at high temperatures above 25 ℃, otherwise it is easy to cause adhesive leakage. However, they have little effect on changes in environmental humidity; If water-soluble adhesives are used, their temperature response to storage conditions is relatively small, and their response to changes in environmental humidity is slightly large. The temperature of storage conditions should be adjusted between 50% and 60%

Considering the climate, high temperature and humidity, it is crucial for adhesive printing companies to pay special attention to avoiding adhesive leakage in adhesive materials. In some areas with high temperature and humidity in the southern region, it is even more important to pay attention to the natural ventilation of storage warehouses. In winter, it is dry and dusty, and adhesive materials (especially thin film adhesive materials) are very prone to static electricity induction, which seriously affects the printing quality. Therefore, the temperature and humidity of the warehouse should be strictly controlled, and companies with conditions can also equip static elimination devices. If the purchased adhesive material contains plastic film packaging, there is no need to damage the plastic film packaging during storage, which will also effectively prevent static electricity induction

2. Warehouse management is very important

Labels are generally produced and processed according to specific orders, with a wide variety of printing categories and different types and specifications of adhesive materials used. Except for some basic materials that may have certain reserves, the vast majority of materials or unique materials (such as film adhesive materials) are purchased according to the production and manufacturing needs of orders, resulting in high material fluidity. The warehouse should be grouped and managed according to the types, specifications, and models of materials, which can not only alleviate inventory pressure and excess consumption, but also better ensure manufacturing quality

The warehouse shall be managed by dedicated personnel. From receiving order information to allocating purchases, the supplier will generally deliver the raw materials to the warehouse within 24 hours. The warehouse manager should carry out project acceptance, filing, and warehousing. Ensure first in, first out (FIFO) during the production and manufacturing of material requisition forms, and properly record and conduct statistical analysis on the return of leftover materials to the warehouse. The inbound and outbound data information should be relative to the enterprise ERP, and inventory levels should be manipulated based on data-driven management to improve the company's efficiency through lean management. Generally, a warehouse should be divided into at least three areas: first, a large storage area, where wooden pallets are used for storage; Secondly, there is a small storage area where materials to be dismantled or remaining in small quantities are placed on display shelves; Thirdly, in the return and exchange area, products that have been prepared for return in advance will be placed on professional greeting boards or wooden pallets

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.