Cold laminated film

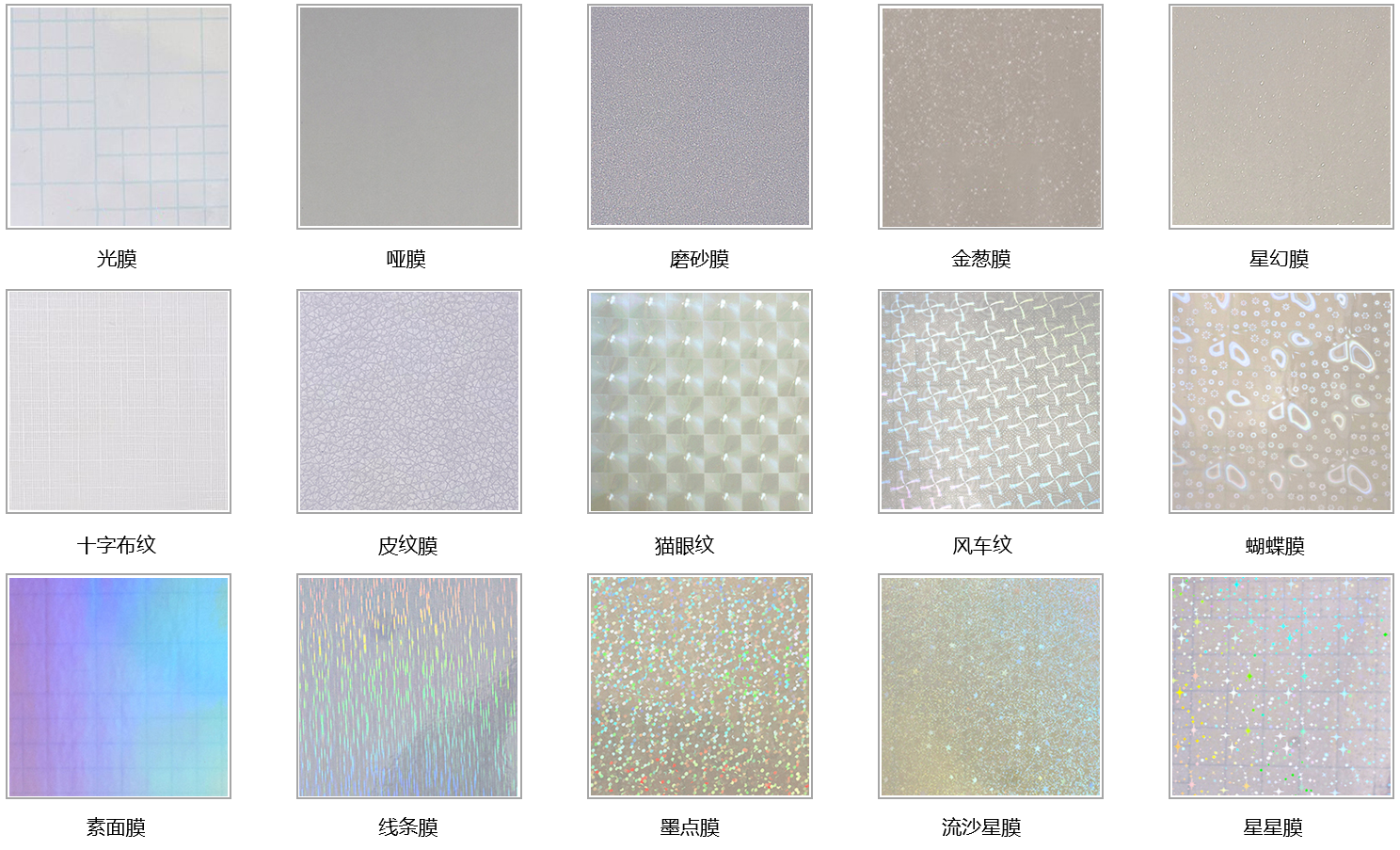

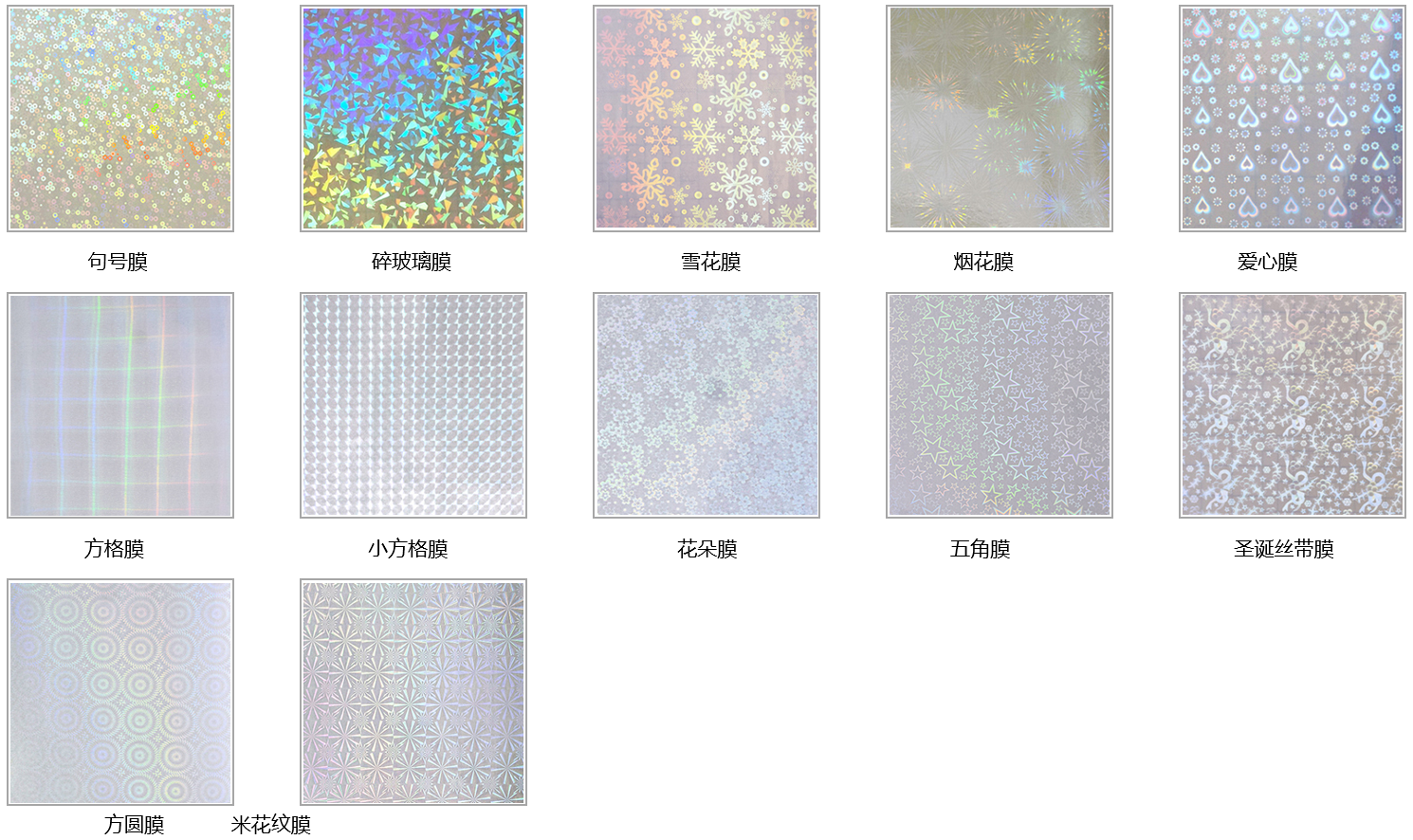

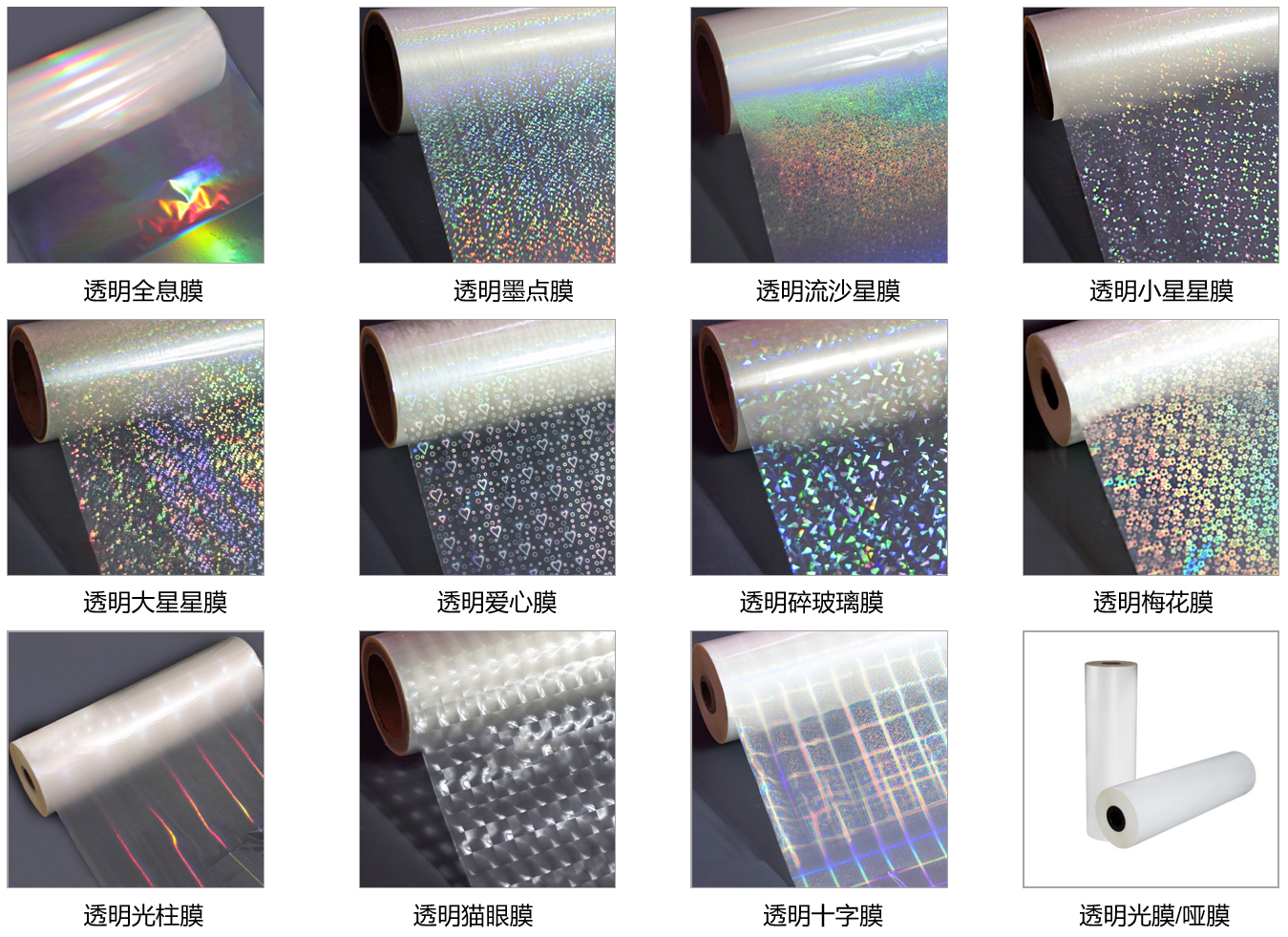

Cold layer film is made of transparent BOPP processed with adhesive. According to the texture of the film surface, it can be divided into light film, matte film, frosted film, star phantom film, holographic film, and special textured protective film. Light film, matte film, and frosted film are widely used in advertising production. Cover the manually or cold pressed photo printing image with a cold pressed film to prevent scratches, contamination, or wetting of the image (printing surface) and protect the image

Cold film can enhance the texture of the image and protect it from scratches and water. However, photo images cannot be highly resistant to corrosion and UV erosion. UV rays can penetrate the cold film and cause the image to fade. Over time, the cold film can also become brittle. Can be widely used in wedding photos, oil painting production, calligraphy and painting, outdoor posters, advertisements, various pictures, documents, materials&hellip& hellip; wait...... Used for large-scale advertising, architectural decoration renderings, background decoration, etc., using cold laminating film for better protection effect

Cutting specifications

Roll specifications

Mother roll: Optical film width: 1280mm, Matte film width: 1260mm, Laser film width: 1200mm, Length: 5000M/roll

Slitting rolls: Optical film/matte film of any width * 400M/roll, laser film of any width * 500M/roll

Axis core: optional: 25mm/75mm

Cutting: 50 sheets/pack * 20 packs * box

Hot pressed film

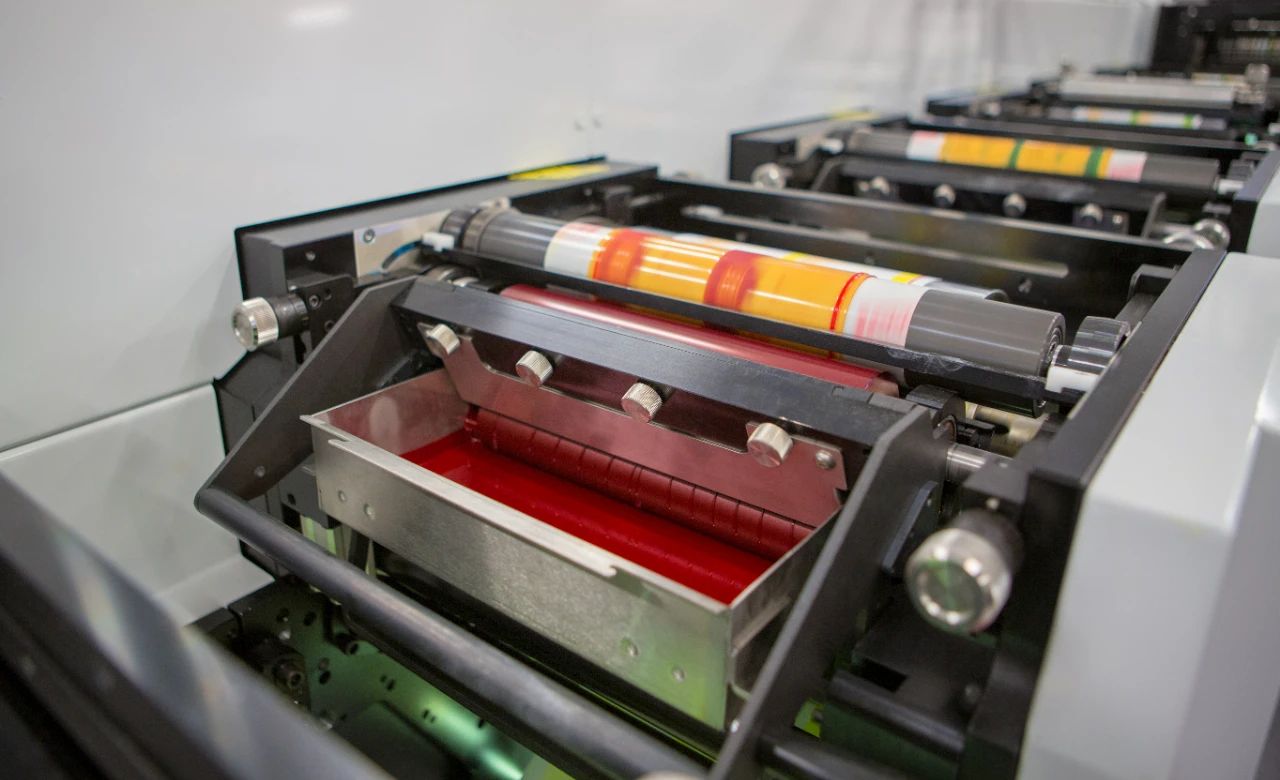

Hot pressed film is a physical and thermal property that forms a molten state at high temperatures. After cooling treatment, a sealed protective space is formed. Hot laminating film requires two processes, hot and cold, to form and maintain stable effects for a long time. However, due to the complexity of the process, specialized machines must be used to produce it, which is a universal method, so the cost is relatively high

Hot laminating film refers to the process of pre gluing and rewinding plastic film, and then laminating it with paper printing. It is first coated by a pre coating processing factory according to the usage specifications and format. After rewinding, the adhesive liquid is applied to the film for the manufacturer to choose from. Then, it is compounded/laminated/coated with adhesive on the film, and heated and pressed together with the paper printed product to form a paper plastic product processing technology. After coating, the printed products have a thin and transparent film on the surface, which makes the surface smoother and brighter, thereby improving the glossiness and fastness of the printed products. The graphic and textual colors are more vivid, full of three-dimensional sense, and also play a role in waterproofing, stain resistance, wear resistance, folding resistance, chemical corrosion resistance, etc

Hot pressed film specifications:

Thickness:

Light film: 20μ m 24μm 22μm 25μm 27μm 28μm 30μm

Matte film: 25μ m 27μm 28μm 30μm

Width: 310~1880 millimeters

Length: 100~3000M

Core diameter: 25.4 millimeters (1 inch), 58 millimeters (2.25 inches), 76 millimeters (3 inches)

Application parameters of hot laminating film

Hot laminating equipment: dry and wet heating laminating machine, heat sealing temperature: 95~105 ℃ (measured temperature), heat sealing pressure: 10-20Mpa, speed: 8-20m/min

Hot stamping film

Hot stamping film, also known as aluminum foil (the term aluminum foil is more commonly used in the printing industry), is a hot stamping material made by coating and vacuum evaporating a thin film substrate with a layer of metal foil. The thickness of aluminum foil is generally (12, 16, 18, 20)μ m. 500-1500mm wide. Electrochemical aluminum foil is made by coating a release layer, a color layer, vacuum aluminum plating, and then coating a glue layer on a thin film, and finally rewinding the finished product

1. Specifications:

Thickness: 0.012mm Width: 0.64m, 1.28m

Length: 120m, 180m, 240m, 300m, 360m, 1000m, 3000m

Standard specification: 0.012mm * 0.64m * 120m

2. Colors: Gold, Silver, Red, Green, Blue, Black, Bronze, Coffee, Matte Gold, Matte Silver, Pearl, Laser, Pigment Foil, etc

3. Type: 1. Sheet 2. Over plastic type 3. Non adhesive type 4. Spray 5. Water pine paper 6. Pigment type 7. Pearl type 8. Hot cloth type

4. Application scope: Suitable for hot stamping various gift packaging boxes, food packaging boxes, tobacco and alcohol packaging boxes, labels, red envelopes, couplets, spring couplets, red envelopes, holiday greeting cards, invitation cards, festive supplies, calendars, written binding tags, trademarks, cosmetics lids, cosmetics hoses, handbags and other paper boxes as well as stationery

5. Hot stamping on various types of paper or cardboard, laminated paper, and plastics such as PC, PS,PP,PET,PVC,OPP,ABS, Imitation leather, etc

6. Product features: clear and beautiful patterns, bright colors, dazzling, wear-resistant, weather resistant, clear contours, suitable for fine patterns, large, medium and small area hot stamping, flat hot stamping and rolling hot stamping, as well as manual, semi-automatic, fully automatic and other hot stamping machines

7. Weight: Gross weight: 1.7KG/roll Net weight: 1.5KG/roll

8. Outer box size: according to customer requirements

9. Packing list: Inner packaging: PET packaging film Outer packaging: 15 standard rolls per box in cardboard boxes

10. Reference hot stamping temperature: Paper type/Over molded type/Spray type/Non adhesive type/Water pine paper type/Pigment type/Pearl type: 100 ℃ -130 ℃, Hot cloth type: 80 ℃ -145 ℃

11. Reference hot stamping time: 0.3S-0.8S

12. Storage conditions: anti pressure, moisture-proof, heat-resistant, sun proof, stored in a cool and ventilated place, with a shelf life of two years

Low surface tension of thin film materials leads to ink loss

Generally speaking, the surface tension of thin film materials needs to reach 38 dynes or above to ensure normal printing, and 42 dynes or above is required for ink to adhere firmly. If ink drop occurs during the printing process, the surface tension value of the material can be tested using a Dyne pen. If it is lower than the above standard, it is recommended to use online corona discharge or coating with base oil to increase the surface tension of the film material, in order to achieve better ink adhesion effect. If there are no conditions to use the above two methods to solve the problem, low surface energy ink can also be used to try to solve it. At present, many ink manufacturers provide inks specifically for low surface energy materials. Printing companies can solve this problem by testing to find an ink that matches the label material used.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.