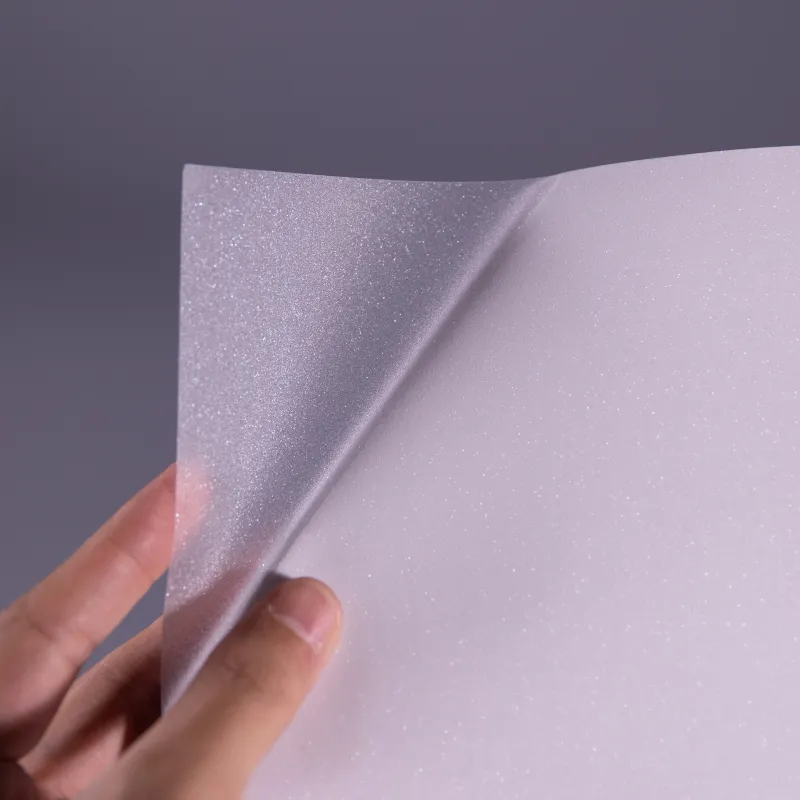

Golden onion flash cold laminating film is a multifunctional surface coating material specially designed for high-end packaging, labels, decoration and creative design. Its unique golden scallion glittering effect, combined with the cold lamination process, endows the product with a luxurious texture and visual impact. At the same time, it features excellent durability and convenient processing performance, and is widely used in printing and packaging, advertising production, gift decoration, brand identification and other fields.

Product Review:Product Name: Golden Onion Flash Cold Laminated Film

Product Introduction:

Golden onion flash cold laminating film is a multifunctional surface coating material specially designed for high-end packaging, labels, decoration and creative design. Its unique golden scallion glittering effect, combined with the cold lamination process, endows the product with a luxurious texture and visual impact. At the same time, it features excellent durability and convenient processing performance, and is widely used in printing and packaging, advertising production, gift decoration, brand identification and other fields.

Product categories of Laminating Film:

Core features:

The surface is coated with high-precision gold scallion particles or glitter coating technology, presenting a fine and uniform metallic luster and glittering effect. Under the illumination of light, it can create a luxurious and eye-catching visual experience, enhancing the product's grade and brand recognition.

No high-temperature heating is required. Through environmentally friendly cold pressing technology, rapid lamination is achieved, avoiding the thermal damage to the substrate (such as paper, plastic, fabric, etc.) caused by traditional hot pressing. It is especially suitable for temperature-sensitive materials.

After lamination, the surface is smooth without bubbles, the adhesion is tight, it is scratch-resistant and anti-fingerprint, effectively extending the service life of the printed matter.

The back is coated with high-quality pressure-sensitive adhesive, which has strong and long-lasting adhesion. It is suitable for various smooth or rough surfaces (such as glass, plastic, metal, wood, etc.), and leaves no residue after being torn off.

It supports various processing methods such as die-cutting, engraving and hand cutting, and is flexible and convenient to operate.

The base material is selected from high-transparency PET or PVC film, which has excellent UV resistance, water resistance and moisture resistance. It is suitable for various indoor and outdoor environments and will not fade or deform after long-term use.

It complies with environmental protection standards such as RoHS and REACH, is safe and non-toxic, and is suitable for scenarios with high safety requirements such as food packaging and children's products.

Application scenarios:

Product Specifications (customizable according to requirements) :

Thickness: 50μm to 200μm

Width: 300mm - 1500mm (for rolls)

Colors: Gold, silver, color gradient, laser dazzling and other diverse options

Viscosity strength: ≥10N/25mm (adjustable as required)

Applicable temperature: -20℃ to 80℃

Reason for selection:

Usage Tips:

Before construction, please ensure that the surface of the base material is clean, dry, free of oil stains or dust.

Store in a cool and dark place (recommended temperature 10℃ to 30℃, humidity ≤60%).

Make your products shine and stand out!

Whether it's enhancing brand image or creating eye-catching creative designs, Jincong Flash cold-laminated self-adhesive Film is your ideal choice. We support customized services. Welcome to contact us for samples and technical support!

Cold Laminating Film Common Question Treatment

1. Insufficient film pressure -- adjust the pressure of the cold mounting machine;

2. The two ends of the cold laminating machine are not smooth -- adjust the adjusting screws of the distance between the cold laminating machines to achieve equal distance;

3. Over-photo paper - the surface of the photo paper is uneven, generally about 25 degrees, placed 2-3 hours will automatically disappear, the higher the temperature will disappear faster;

4. Over PP glue --A. hand touch PP glue screen if there is no "rough" feeling, then according to the above method; B. There is a "rough" feeling that requires more PP backing glue;

5. Glue viscosity is not good at low temperature --A. Improve the use of ambient temperature. B. Replace the cold mounting film

1. The glue is not sticky enough --A. Increase the ambient temperature,B. Replace the cold mounting film;

2. Thin glue - the general distance is not long, the probability of greater before and after shutdown, generally pull off a few meters;

3.PP adhesive surface hand touch "rough" feeling --A. Replace PP adhesive,B. Or use studio film over the picture;

4. There is dust in the air --A. Purify the operating environment,B. Close the blower or air inlet source;

5. Water droplets (such as saliva) inadvertently splash on the surface of the spray painting --A. Pay attention when operating, especially when speaking, do not face the picture,B. Air temperature in dry environment, such as air conditioning, hot fan or ventilation.

1. The glue does not "mature" -- change the cold mounting film

1. The glue is not "matured" thoroughly -- open the cold mounting film

Pack and place in the air for 2-5 days to allow the glue to fully "mature" under natural conditions;

2. The picture is not sufficiently dry, especially in winter, because there are antifreeze components in the winter ink, which is not easy to volatilize completely.- Let the picture be fully dry, the general winter time is twice as long as summer and autumn above, and then over the painting (must pay attention to dust);

3. Large area single color such as: all black/all red, etc. --A. Light color,B. Replace ink,C. Fully dry the picture (completely dry),D. heat the picture,E. replace the more viscous cold mounting film, the thinner the better.

4. The ambient temperature is low, so that the cold laminating film surface is too hard -- improve the ambient temperature when using;

5. Cold mounting film is too thick -- replace it with a thin cold mounting film;

6. Roll up immediately after painting, the glue and the picture are not fully integrated - after painting, place it flat for more than 45 minutes and then roll it up.

7. Aging glue -- Replace the cold mounting film.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

The Flash Cold Laminating Film is amazing! It provides a smooth, glossy finish and is super easy to use