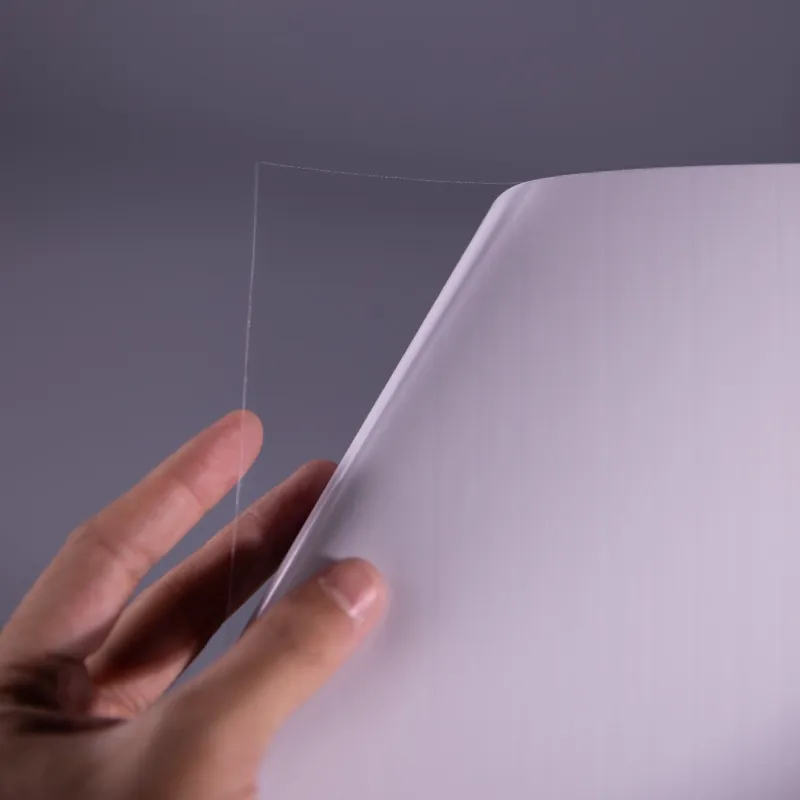

Clear transparent glass cold laminating film is an innovative material specially designed for surface protection, enhancing visual effects and extending the lifespan of signs. Made of high-transparency PET substrate and environmentally friendly pressure-sensitive adhesive technology, it can be easily bonded without the need for hot pressing equipment. It is suitable for various scenarios such as printed materials, signs, and packaging, providing long-lasting gloss and anti-wear performance.

Product Review:Product Name: Clear transparent glass cold laminating film

Product Overview

Clear transparent glass cold laminating film is an innovative material specially designed for surface protection, enhancing visual effects and extending the lifespan of signs. Made of high-transparency PET substrate and environmentally friendly pressure-sensitive adhesive technology, it can be easily bonded without the need for hot pressing equipment. It is suitable for various scenarios such as printed materials, signs, and packaging, providing long-lasting gloss and anti-wear performance.

Product categories of Laminating Film

Glass Cold Laminating Film Product Overview

Clear transparent glass cold laminating film is an innovative material specially designed for surface protection, enhancing visual effects and extending the lifespan of signs. Made of high-transparency PET substrate and environmentally friendly pressurCore characteristics

Optical-grade transparent substrate with a light transmittance of over 98%, no bubbles or fog after lamination, perfectly reproducing the color and details of the pattern, enhancing the visual texture of printed materials and labels.

High-performance pressure-sensitive adhesive layer, with stable adhesion, can firmly adhere to the surfaces of various materials such as paper, plastic, and metal, and is resistant to peeling and edge lifting. It features water resistance, scratch resistance and UV aging resistance, which can extend the service life of the adhered object.

No heating or professional equipment is required. The bonding can be completed by hand, saving time and cost. Supports immediate use upon application, with no residual glue stains, suitable for small-batch customization or large-scale industrial applications.

Certified by RoHS, it is solvent-free, non-toxic and odorless, and suitable for fields with strict environmental protection requirements such as food packaging and children's products. Compatible with various processes such as inkjet printing, screen printing and digital printing.

Glass Cold Laminating Film Typical application scenarios

Advertising signs: Transparent lamination protection for outdoor posters, window stickers, and vehicle body advertisements.

Packaging and printing: High-gloss coating and anti-stain treatment for book covers, gift box labels, and bottle stickers.

Electronic products: Temporary protective film for touch screens, scratch-resistant lamination for instrument panel markings.

DIY creativity: Transparent sealing and reinforcement for handicrafts, photo albums, and decorative paintings.

Glass Cold Laminating Film Technical parameters

Substrate thickness: 50μm/75μm/100μm (optional)

Light transmittance: ≥98%

Adhesive force: ≥3.5N/25mm

Temperature resistance range: -20℃ to 80℃

Shelf life: 24 months (Store in a cool and dark place)

Glass Cold Laminating Film Usuggestions

Before bonding, ensure that the surface to be bonded is clean, dry, free of grease and dust.

Use a scraper or soft cloth to remove air bubbles from the center to the edge for a smoother fit.

If removal is necessary, it can be peeled off slowly and at a constant speed to avoid the residue of the adhesive layer.

Glass Cold Laminating Film Packaging specification

A4 and A3 sizes are supported, and slitting customization is available.

Glass Cold Laminating FilmBrand commitment

We are committed to providing industrial-grade quality lamination solutions, supporting sample trials and customized services to ensure your projects receive the best protection and display effects.

Cold Laminating Film Common Question Treatment

1. Insufficient film pressure -- adjust the pressure of the cold mounting machine;

2. The two ends of the cold laminating machine are not smooth -- adjust the adjusting screws of the distance between the cold laminating machines to achieve equal distance;

3. Over-photo paper - the surface of the photo paper is uneven, generally about 25 degrees, placed 2-3 hours will automatically disappear, the higher the temperature will disappear faster;

4. Over PP glue --A. hand touch PP glue screen if there is no "rough" feeling, then according to the above method; B. There is a "rough" feeling that requires more PP backing glue;

5. Glue viscosity is not good at low temperature --A. Improve the use of ambient temperature. B. Replace the cold mounting film

1. The glue is not sticky enough --A. Increase the ambient temperature,B. Replace the cold mounting film;

2. Thin glue - the general distance is not long, the probability of greater before and after shutdown, generally pull off a few meters;

3.PP adhesive surface hand touch "rough" feeling --A. Replace PP adhesive,B. Or use studio film over the picture;

4. There is dust in the air --A. Purify the operating environment,B. Close the blower or air inlet source;

5. Water droplets (such as saliva) inadvertently splash on the surface of the spray painting --A. Pay attention when operating, especially when speaking, do not face the picture,B. Air temperature in dry environment, such as air conditioning, hot fan or ventilation.

1. The glue does not "mature" -- change the cold mounting film

1. The glue is not "matured" thoroughly -- open the cold mounting film

Pack and place in the air for 2-5 days to allow the glue to fully "mature" under natural conditions;

2. The picture is not sufficiently dry, especially in winter, because there are antifreeze components in the winter ink, which is not easy to volatilize completely.- Let the picture be fully dry, the general winter time is twice as long as summer and autumn above, and then over the painting (must pay attention to dust);

3. Large area single color such as: all black/all red, etc. --A. Light color,B. Replace ink,C. Fully dry the picture (completely dry),D. heat the picture,E. replace the more viscous cold mounting film, the thinner the better.

4. The ambient temperature is low, so that the cold laminating film surface is too hard -- improve the ambient temperature when using;

5. Cold mounting film is too thick -- replace it with a thin cold mounting film;

6. Roll up immediately after painting, the glue and the picture are not fully integrated - after painting, place it flat for more than 45 minutes and then roll it up.

7. Aging glue -- Replace the cold mounting film.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(1)

OwnlikesThe Clear Transparent Glass Laminating Film is impressive. It provides a smooth, crystal-clear finish that enhances the appearance of any project. The durability and clarity are exceptional.