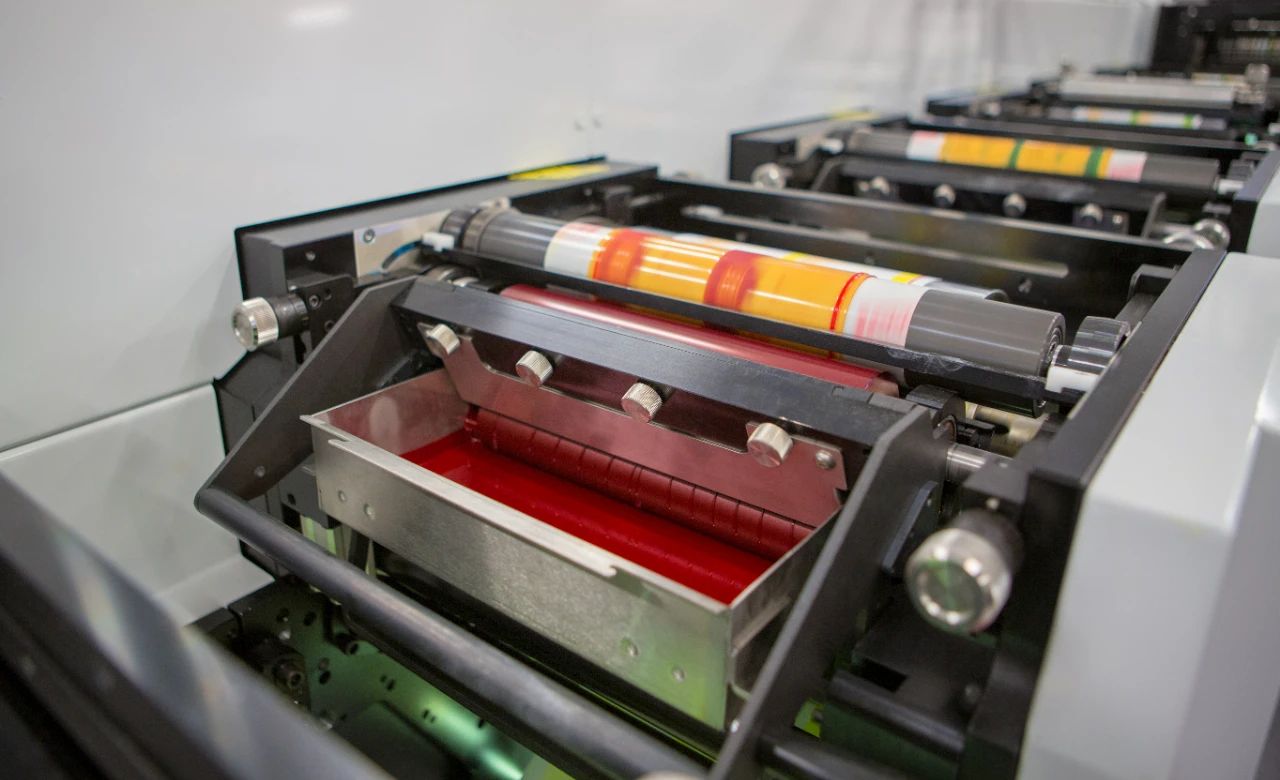

Low surface tension of thin film materials leads to ink loss

Generally speaking, the surface tension of thin film materials needs to reach 38 dynes or above to ensure normal printing, and 42 dynes or above is required for ink to adhere firmly. If ink drop occurs during the printing process, the surface tension value of the material can be tested using a Dyne pen. If it is lower than the above standard, it is recommended to use online corona discharge or coating with base oil to increase the surface tension of the film material, in order to achieve better ink adhesion effect. If there are no conditions to use the above two methods to solve the problem, low surface energy ink can also be used to try to solve it. At present, many ink manufacturers provide inks specifically for low surface energy materials. Printing companies can solve this problem by testing to find an ink that matches the label material used.

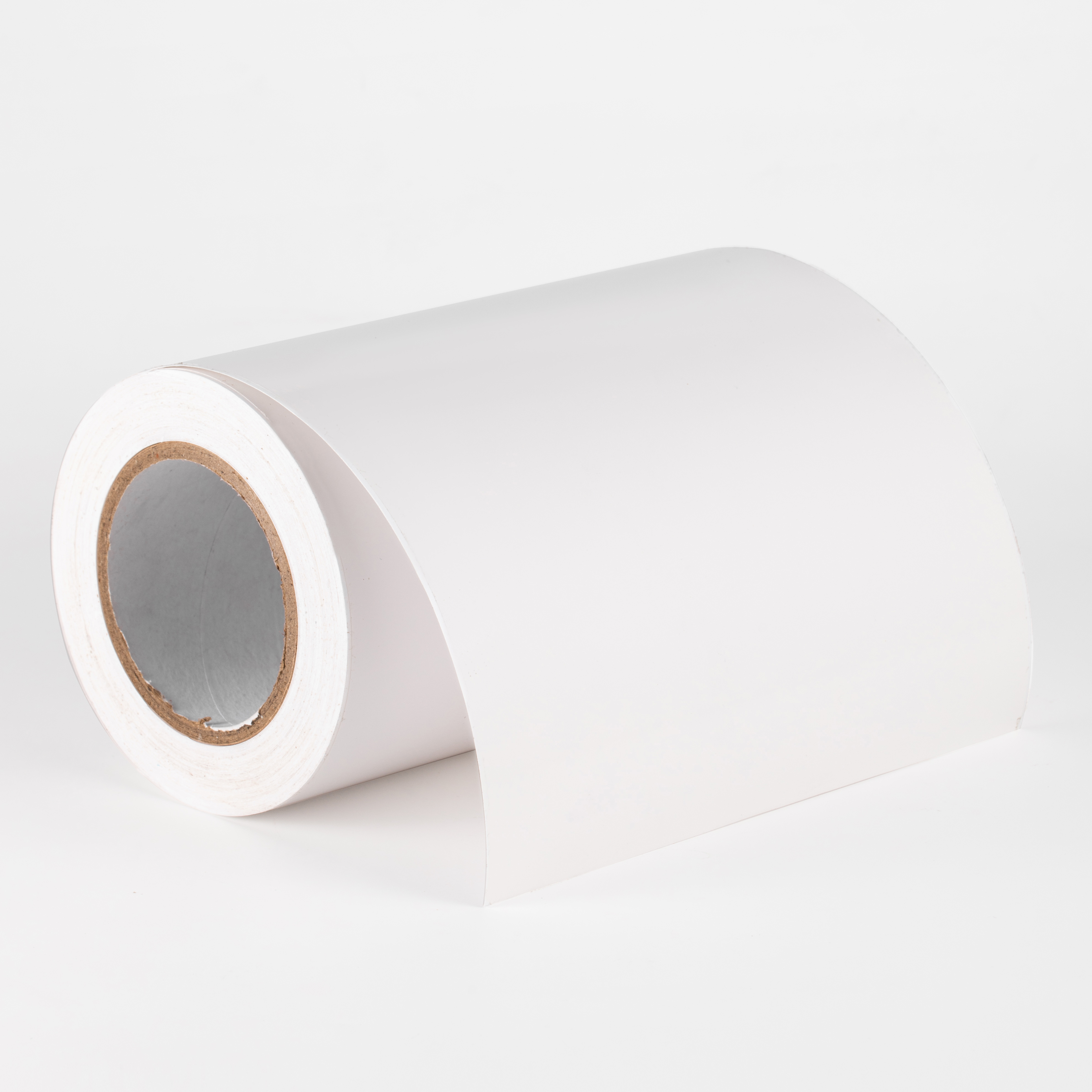

BOPP biaxially oriented polypropylene film

BOPP adhesive label; BOPP is; Biaxially Oriented Polypropylene” The abbreviation is biaxially oriented polypropylene film. The production method is to first make a sheet or thick film of polymer polypropylene melt through a narrow machine head, and then in a dedicated stretching machine, under certain temperature and set speed conditions, vertically pull it out in two directions (longitudinal and transverse) at the same time or step by step, and make a thin film through appropriate cooling or heat treatment, or special processing (such as corona discharge, coating, etc.)

BOPP material composition:

1. Raw material: BOPP adhesive material< br /> 2. Adhesive: General adhesive, universal strong adhesive, special labeling requirements can be customized with adhesive< br /> 3. Bottom paper classification: Bottom paper can be divided into white, blue, yellow, thick white, economic yellow, etc

Advantages of BOPP material:

1. Good mechanical properties: BOPP film undergoes biaxial stretching during production and has excellent mechanical properties. It has good impact resistance, crease resistance, friction resistance and other properties< br /> 2. Non toxic and odorless: BOPP film is made of food grade raw materials, which are non-toxic and odorless, and meet the requirements of food safety< br /> 3. High transparency: BOPP film has high transparency, which can clearly display the contents of the sticker and improve the appearance quality of the product< br /> 4. Good moisture resistance: BOPP film has a certain degree of moisture resistance, which can prevent moisture from entering the packaging to a certain extent and extend the shelf life of the product< br /> 5. Excellent heat sealing performance: BOPP film has good heat sealing performance and can be heat sealed at lower temperatures, reducing production costs< br /> 6. Wide application range: BOPP film can be made into different types of labels, packaging bags, tapes, etc., with a very wide range of applications

Disadvantages of BOPP material:

1. High price: Compared to other ordinary plastic films, BOPP film has a higher price, which increases production costs< br /> 2. Sensitive to temperature and humidity: BOPP film is sensitive to temperature and humidity, and is prone to deformation, shrinkage, discoloration, and other issues in high temperature and high humidity environments< br /> 3. Easy to scratch: Due to the low surface hardness of BOPP film, it is prone to scratches, which affects its aesthetics and usability< br /> 4. Not easy to recycle: BOPP film is not easy to recycle and reuse, which has a certain impact on the environment

The future development of BOPP adhesive labels may face the following directions:

1. Functional enhancement: BOPP adhesive labels may develop more special functions, such as waterproofing, oil resistance, sun protection, etc., to improve the shelf life of products< br /> 2. Environmental sustainability: Environmental protection and sustainability will become the focus of attention, and manufacturers may use more renewable materials to reduce their impact on the environment< br /> 3. Intelligent production: Utilizing advanced technologies such as artificial intelligence and big data to improve production efficiency and reduce costs< br /> 4. Application field expansion: BOPP adhesive labels may expand to more fields, such as pharmaceuticals, cosmetics, personal care products, etc

BOPP series adhesive material list

Digital printing of vulcanized transfer film

A rubber specific transfer film based on vulcanization process, comprising a substrate and an ink layer printed on the substrate, wherein the melting temperature of the substrate is not higher than the vulcanization temperature in the vulcanization process, and the material of the substrate can dissolve with rubber at the vulcanization temperature. The present invention also provides a vulcanization transfer printing method for rubber products, in which the rubber specific transfer film described in the present invention is attached to the surface of the rubber semi-finished product, and subjected to a pressure of 6-11kg/cm at 140-160C

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.