The Challenges Faced by Inkjet Printers in Printing Adhesive stickers

Sticker labels have become an integral part of various industries, serving as a crucial means of communication, branding, and product identification. However, the efficient production of adhesive stickers is not without its challenges. One significant hurdle is the difficulty faced by inkjet printers in effectively printing adhesive stickers. In this article, we will delve into the intricacies of this issue and explore potential solutions.

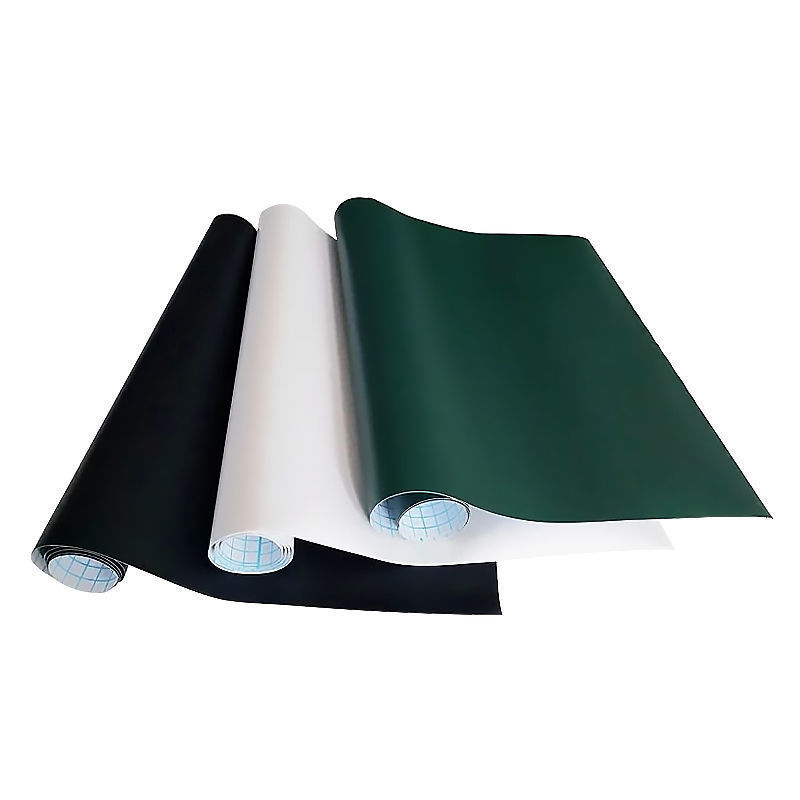

The Nature of Adhesive Stickers

Adhesive stickers differ from standard paper in terms of material and surface characteristics. The adhesive layer, which allows the sticker to adhere to various surfaces, poses a unique challenge for inkjet printers. Traditional inkjet printing methods often encounter difficulties in ensuring proper ink adhesion and durability on these specialized surfaces.

Challenges in Ink Adhesion

One of the primary challenges inkjet printers face when dealing with adhesive stickers is achieving satisfactory ink adhesion. The adhesive layer tends to repel ink, leading to issues such as smudging, uneven color distribution, and compromised print quality. These challenges are exacerbated when using water-based inks, which are commonly employed in inkjet printers.

Compatibility Issues

Another aspect contributing to the problem is the compatibility between ink formulations and sticker materials. The diverse range of materials used in adhesive stickers requires tailored ink formulations to ensure optimal adhesion and longevity. Inkjet printers, designed for more conventional printing substrates, may struggle to accommodate these specialized requirements.

Print Durability

Print durability is a critical factor in the production of adhesive stickers, especially when they are subjected to varying environmental conditions. Inkjet-printed stickers often face challenges in maintaining their integrity over time, particularly in situations involving exposure to moisture, heat, or other external factors. Achieving a balance between vibrant color reproduction and durability remains a persistent issue.

Exploring Potential Solutions

Addressing the challenges faced by inkjet printers in printing adhesive stickers requires a multifaceted approach. Researchers and industry experts are actively exploring innovative solutions to enhance ink adhesion, improve compatibility, and ensure print durability.

Advanced Ink Formulations

Developing ink formulations specifically tailored for adhesive stickers is a key area of research. Advanced ink formulations with enhanced adhesion properties can mitigate the challenges associated with traditional water-based inks. Solvent-based and UV-curable inks are being explored for their potential to provide better adhesion on adhesive surfaces.

Surface Treatment Technologies

Surface treatment technologies offer another avenue for improving ink adhesion on adhesive stickers. Pre-treating the sticker surface to enhance ink receptivity has shown promise in overcoming the repellent nature of adhesive layers. Plasma treatment and corona discharge are among the techniques being investigated for their effectiveness in promoting ink adhesion.

Printer Modification and Innovation

Modifying existing inkjet printers or developing specialized printers for adhesive sticker printing is a proactive approach to address compatibility issues. Innovations in printer design, printhead technology, and ink delivery systems are being explored to create printers capable of handling the unique challenges posed by adhesive sticker materials.

Conclusion

The challenges faced by inkjet printers in printing adhesive stickers underscore the need for continuous innovation in the sticker label industry. As the demand for high-quality, durable stickers continues to rise, researchers and industry professionals are collaborating to overcome the technical hurdles associated with ink adhesion, compatibility, and print durability. Through advancements in ink formulations, surface treatment technologies, and printer design, the sticker label industry is poised for a future where inkjet printers can seamlessly meet the demands of this dynamic and essential market.

We offer comprehensive technical support, including free professional labeling solutions, advice on label materials and adhesive selection, as well as online/offline assistance from professional software and hardware engineers. Service email: andy@ownlikes.cn. In pre-sales, we leverage our extensive experience in specialty labeling projects to provide clients with the most suitable hardware solutions. Additionally, all our label barcode printers and scanners come with a three-year free warranty, demonstrating our confidence in our products.

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.