Colored foil stamping paper is a decorative material specifically designed for hot stamping processes. Through high-temperature and high-pressure application, it transfers the metallic luster and colorful layers onto the surface of the substrate, creating a dazzling and colorful hot stamping effect. It features rich colors, high gloss, and strong adhesion, and is widely used in packaging, printing, labels, gifts, stationery, and other fields, enhancing the high-end texture and visual appeal of products.

Product Review:Product Introduction of Colored Electrolytic Aluminum Foil Hot Stamping Paper

Foil Paper Product Overview

Colored foil stamping paper is a decorative material specifically designed for hot stamping processes. Through high-temperature and high-pressure application, it transfers the metallic luster and colorful layers onto the surface of the substrate, creating a dazzling and colorful hot stamping effect. It features rich colors, high gloss, and strong adhesion, and is widely used in packaging, printing, labels, gifts, stationery, and other fields, enhancing the high-end texture and visual appeal of products.

Foil Paper Product Features

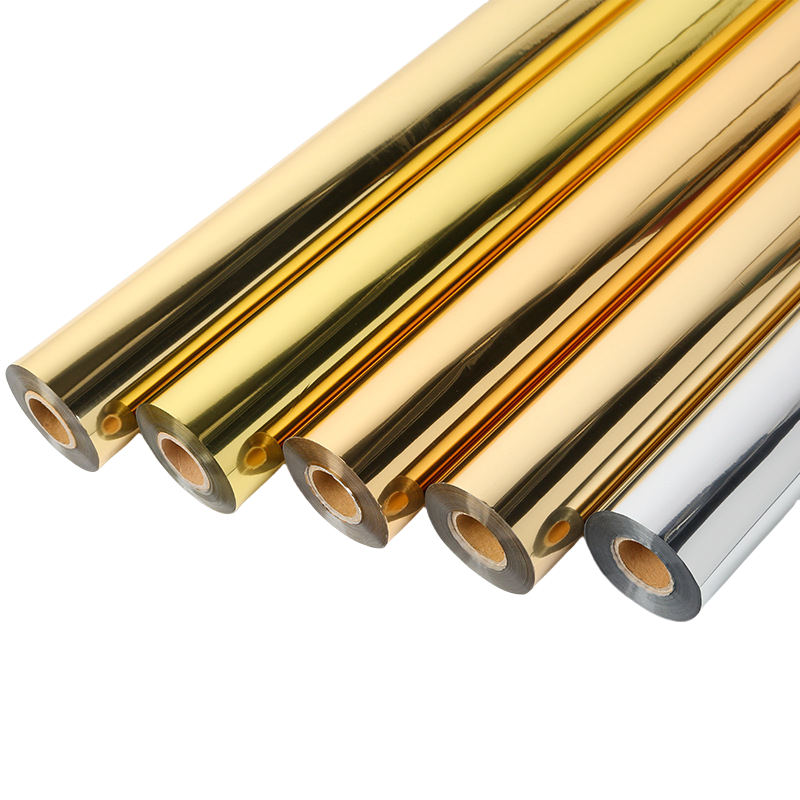

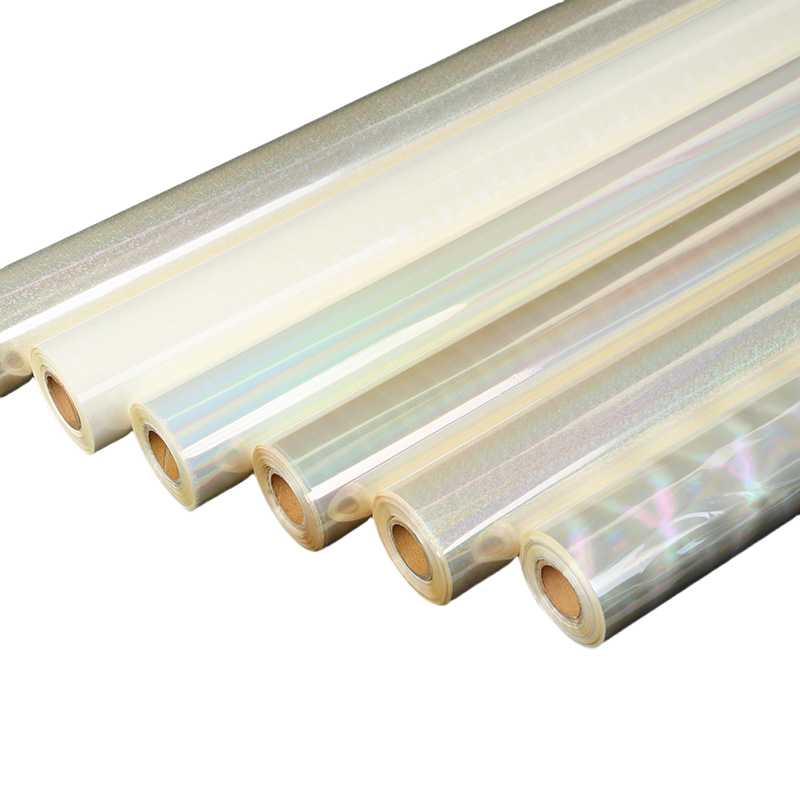

We offer dozens of standard colors such as gold, silver, red, blue, green, and purple, and support custom special colors to meet diverse design requirements.

Using vacuum aluminum plating technology, the metal layer is fine and lustrous. Combined with a colored coating, it presents a three-dimensional and glittering effect.

It is suitable for various materials such as paper, plastic, leather and wood, and is not easy to fall off or scratch after hot stamping.

Environmental protection and safety

It complies with international environmental standards such as RoHS and REACH, has no toxic substance residues, and is suitable for sensitive fields such as food packaging.

Some series feature UV resistance, high-temperature resistance, and anti-oxidation properties, and will not fade even after long-term use.

Electrolytic Aluminum Foil Paper Film Product

Foil Paper Technical Parameters

Material structure: PET film + release layer + color layer + aluminum coating layer + adhesive layer

Hot stamping temperature: 120°C - 180°C (adjust according to model)

Hot stamping speed: 0.5 - 1.5 seconds (suggested pressure: 4 - 6 kg/cm²)

Roll material specifications: Width 200mm - 1200mm, Length 200m - 3000m (can be slit)

Foil Paper Application Scenarios

High-end packaging: Logo or pattern hot stamping for cigarette and alcohol boxes, cosmetic boxes, and luxury gift boxes.

Printed materials: book and periodical covers, greeting cards, and title or border decorations for certificates.

Anti-counterfeiting gold hot stamp labels for electronic products and clothing tags.

Personalized pattern design for cultural and creative products: notebooks and photo albums.

Foil Paper Precautions for Use

Before hot stamping, it is necessary to test the material compatibility and adjust the optimal temperature and pressure.

Store in a cool and dry place (suggested temperature 10°C - 30°C), away from direct sunlight.

It is recommended to confirm the color and effect with a sample before mass production.

Foil Paper Service Support

Provide sample delivery, technical guidance and customized solutions.

Support OEM/ODM cooperation. Special effects (such as 3D embossing, laser color-changing, etc.) can be developed according to customer requirements.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I love how vibrant and reflective this Color Foil Paper Film is—perfect for making my crafts stand out

I recently used the Color Foil Paper Film for a DIY project, and it exceeded my expectations. The vibrant colors and glossy finish gave my crafts a professional look. It was easy to cut and apply, though it took a bit of practice to avoid wrinkles. Durable and eye-catching, I’d definitely recommend it for creative projects