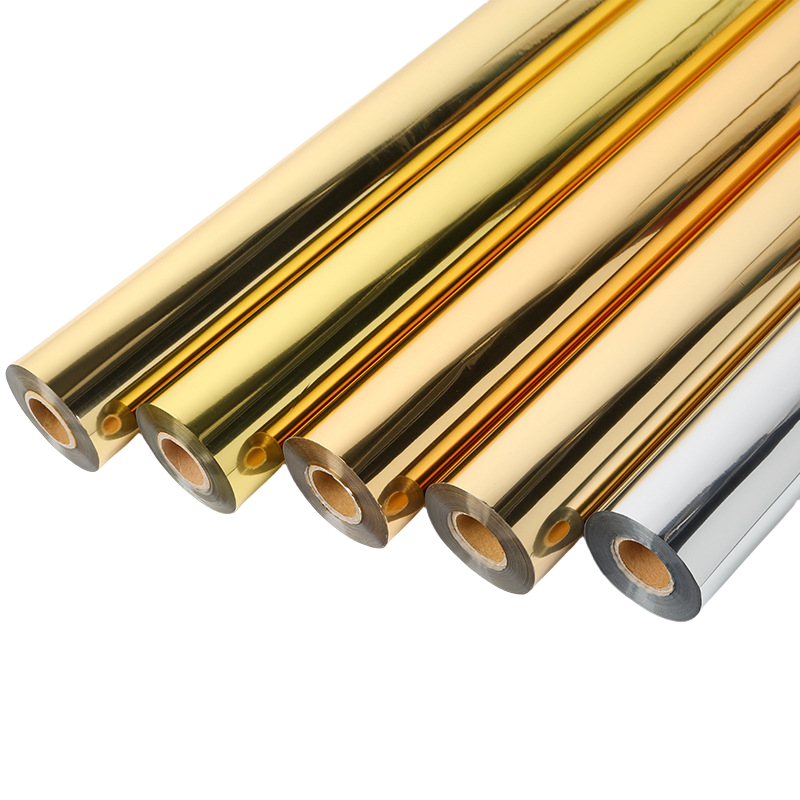

Matte gold silver foil paper is a high-end embossing material. It is made with a special matte coating process, combining the metallic texture with a low-key and soft visual effect. Compared to traditional glossy foil paper, the matte series appears more elegant and restrained, and is suitable for packaging, printing, and decoration fields that seek luxury, artistic appeal, or retro styles.

Product Review:Foil Paper Product Overview

Matte gold silver foil paper is a high-end embossing material. It is made with a special matte coating process, combining the metallic texture with a low-key and soft visual effect. Compared to traditional glossy foil paper, the matte series appears more elegant and restrained, and is suitable for packaging, printing, and decoration fields that seek luxury, artistic appeal, or retro styles.

Foil Paper Product Features

The surface has no high reflectivity, presenting a delicate and soft metallic luster, which avoids harsh reflections and enhances the product's quality.

The texture is smooth and the matte finish remains unchanged for a long time.

Matte gold: Low-key yet luxurious, suitable for high-end gifts and book covers.

Matte silver: Modern and minimalist, commonly used in technological products and fashionable packaging.

Suitable for various materials (paper, leather, wood, plastic, etc.), the heat stamping is firm and does not come off.

Compliant with RoHS standards, without irritating odors; resistant to scratching and oxidation, and does not fade even after long-term storage.

Electrolytic Aluminum Foil Paper Film Product

Foil Paper Application Scenario

Packaging Printing: Luxury boxes, packaging for cigarettes and alcohol, cosmetic gift boxes.

Cultural Creativity: Book binding, greeting cards, notebook covers.

Commercial decoration: Brand logo, tags, menu embossing.

Wedding supplies: Invitations, sweet boxes with matte gold embossing and embellishments.

Foil Paper Technical Specifications

Material PET film + matte metal coating

Width Standard 640mm (customizable)

Applicable Temperature 100-130℃ (adjustable according to material)

Sticking Method Both flat sticking and roller sticking are applicable

Foil Paper Customer Value

Enhance product appearance: Matte effect avoids a cheap look, suitable for high-end positioning.

Differentiated design: In sharp contrast to the common shiny gold embossing in the market, it enhances the visual memory points.

Operation is convenient: Compatible with most die-cutting machines, no special equipment required.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I used the Matte Gold Silver Foil Paper Film for some packaging, and it worked out great. The matte finish looks elegant, and the foil adds a nice touch without being too shiny. Perfect for giving things a more premium feel.

I’ve been using the Matte Gold Silver Foil Paper Film for a few DIY projects, and it’s been amazing. The matte finish looks elegant, and the paper is thick yet easy to cut and shape. It’s perfect for creating custom cards, gift wraps, and even some small decor pieces. The gold and silver tones are just the right amount of shine, not too flashy. Definitely a solid choice for anyone into crafts!