Holographic electroplated aluminum embossing film is a special film material produced through processes such as vacuum aluminum plating and laser embossing. It is widely used for surface embossing decoration in packaging printing, labels, gifts, cigarette and alcohol boxes, cosmetic boxes, etc. Its unique laser holographic effect can significantly enhance the product's grade, providing visual impact and anti-counterfeiting functions.

Product Review:Introduction to Holographic Electroplated Aluminum Embossing Film Products

——High Gloss · High Precision · Environmentally Friendly Embossing Solution

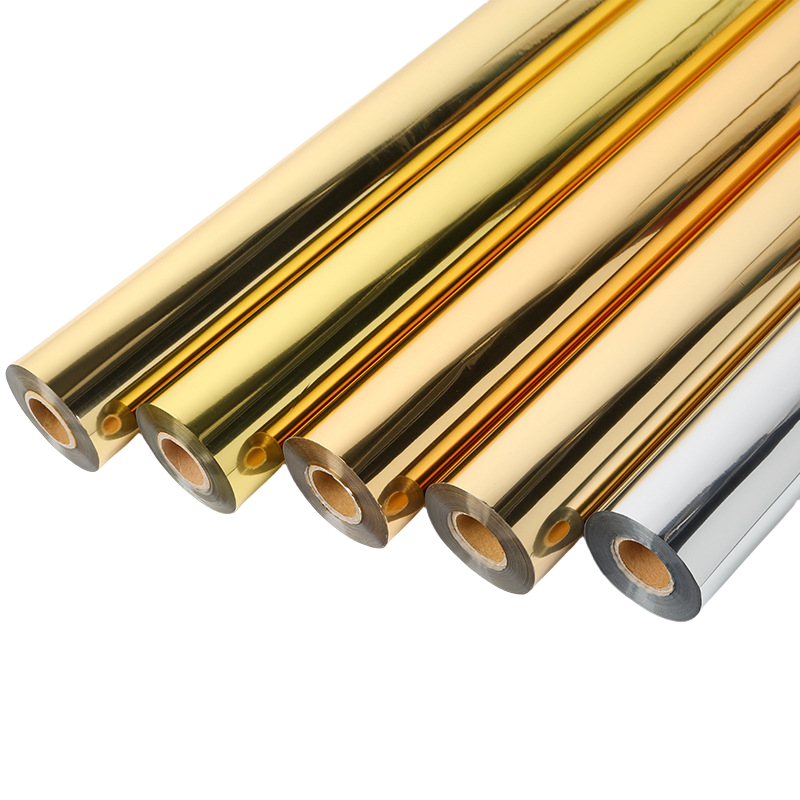

Electroformed Aluminum Film Product Overview

Holographic electroplated aluminum embossing film is a special film material produced through processes such as vacuum aluminum plating and laser embossing. It is widely used for surface embossing decoration in packaging printing, labels, gifts, cigarette and alcohol boxes, cosmetic boxes, etc. Its unique laser holographic effect can significantly enhance the product's grade, providing visual impact and anti-counterfeiting functions.

Electroformed Aluminum Film Key Features

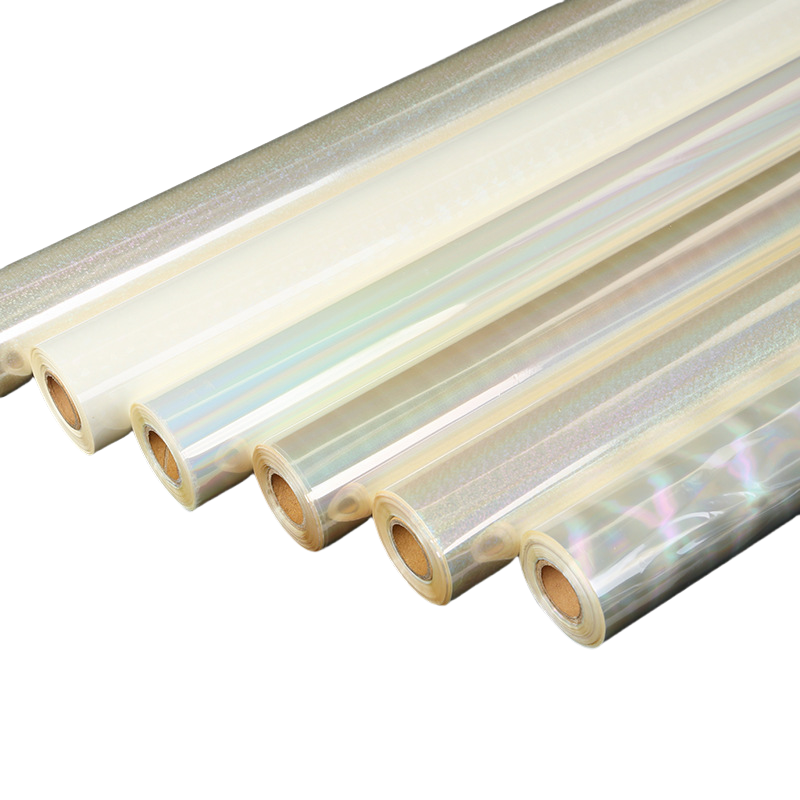

Using precise laser molding technology, it presents dynamic, colorful, three-dimensional holographic patterns. Under the refraction of light, it can display multi-layered rainbow-like luster.

It is suitable for various materials such as paper, plastic (PVC/PP/PET), leather, and wood, and the heat stamping is firm and does not come off.

Compliant with international environmental protection standards such as RoHS and REACH, it contains no benzene or ketone. It is suitable for applications in fields with high safety requirements, such as food and pharmaceutical packaging.

High temperature resistant and scratch-resistant, suitable for high-speed stamping machines (flat-to-flat / round-to-round), enhancing production efficiency.

Customizable laser anti-counterfeiting features such as micro-printed text and dynamic color-changing effects can help protect the brand.

Electrolytic Aluminum Foil Paper Film Product

Electroformed Aluminum Film Technical Parameters

Material structure: PET film + release layer + holographic layer + aluminum coating layer + adhesive layer

Hot stamping temperature: 120°C - 180°C (adjust according to model)

Hot stamping speed: 0.5 - 1.5 seconds (suggested pressure: 4 - 6 kg/cm²)

Roll material specifications: Width 200mm - 1200mm, Length 200m - 3000m (can be slit)

Electroformed Aluminum Film Application Scenarios

High-end packaging: Logo or pattern hot stamping for cigarette and alcohol boxes, cosmetic boxes, and luxury gift boxes.

Printed materials: book and periodical covers, greeting cards, and title or border decorations for certificates.

Anti-counterfeiting gold hot stamp labels for electronic products and clothing tags.

Personalized pattern design for cultural and creative products: notebooks and photo albums.

Electroformed Aluminum Film Precautions for Use

Before hot stamping, it is necessary to test the material compatibility and adjust the optimal temperature and pressure.

Store in a cool and dry place (suggested temperature 10°C - 30°C), away from direct sunlight.

It is recommended to confirm the color and effect with a sample before mass production.

Electroformed Aluminum Film Service Support

Provide sample delivery, technical guidance and customized solutions.

Support OEM/ODM cooperation. Special effects (such as 3D embossing, laser color-changing, etc.) can be developed according to customer requirements.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I’ve already used the Holographic Electroformed Aluminum Film, and it’s fantastic. The holographic shine is eye-catching, and the material feels really durable. It’s a great choice for adding some extra flair to my projects.

I’ve been using the Holographic Electroformed Aluminum Film for some creative projects, and I’m really happy with it. The holographic effect is vibrant and eye-catching, making any design pop. It’s easy to work with, cuts cleanly, and adds a sleek, shiny finish to my crafts. It’s a great material for anyone who loves unique, high-quality designs. Definitely will buy again!