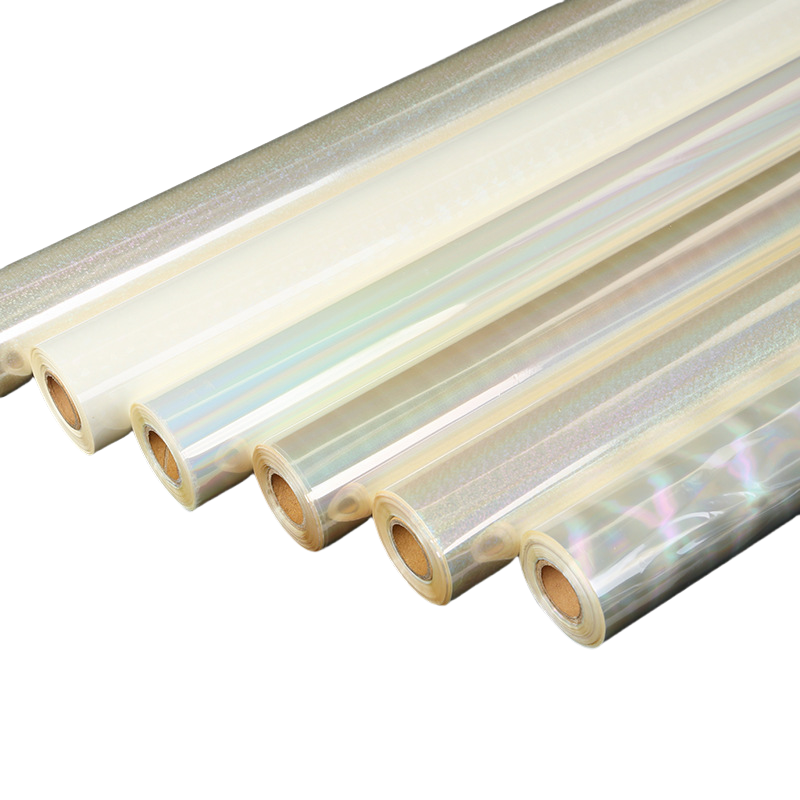

The Colorful foil paper is a type of embossing material made through advanced coating technology and multi-layer coating process. Its surface exhibits a brilliant and colorful metallic luster, which changes into a rainbow-like color effect with the variation of light angles. It is suitable for embossing on various materials such as paper, plastic, leather, and textiles, and is widely used in industries like packaging, printing, gifts, and clothing to enhance the product's high-end texture and visual appeal.

Product Review:Introduction to Colorful Foil Paper Film Products

Product Name: Colorful Foil Paper Film

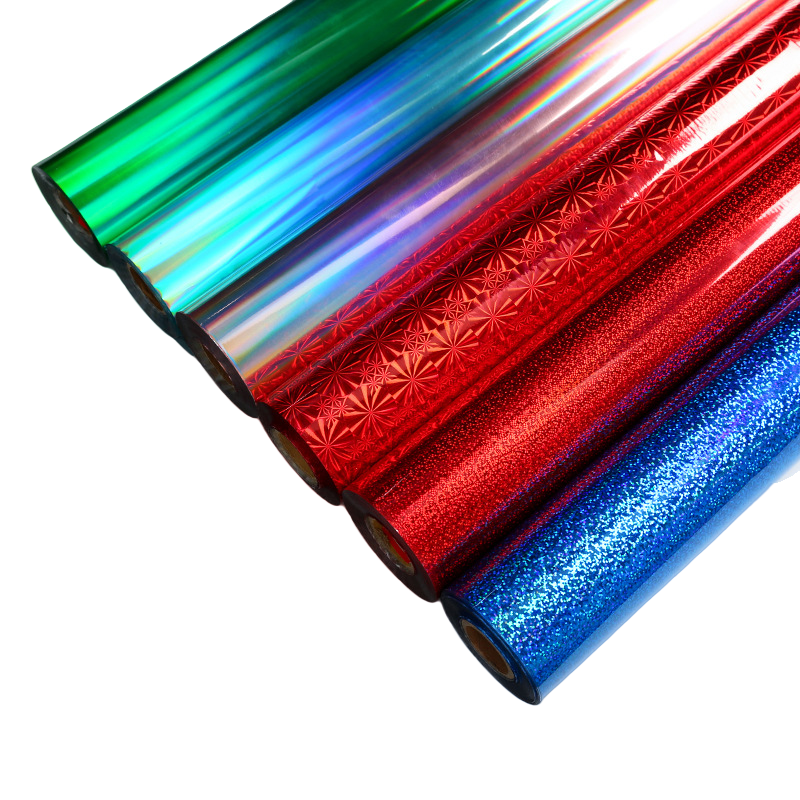

Product Features: High gloss, multi-color brilliance, environmentally friendly and durable, wide range of applications

Product Overview

The Colorful foil paper is a type of embossing material made through advanced coating technology and multi-layer coating process. Its surface exhibits a brilliant and colorful metallic luster, which changes into a rainbow-like color effect with the variation of light angles. It is suitable for embossing on various materials such as paper, plastic, leather, and textiles, and is widely used in industries like packaging, printing, gifts, and clothing to enhance the product's high-end texture and visual appeal.

Core Advantages

The unique multi-layer optical coating design enables a gradual color change effect of red, blue, green, and purple, enhancing the product's grade and artistic appeal.

Under the effect of light refraction, there are dynamic color changes, which is suitable for creating eye-catching packaging or decorative designs.

Using environmentally friendly polymer materials, the product will not fall off after heat stamping, is resistant to wear and scratch, and maintains bright colors for a long time.

High temperature resistance (-20℃ to 120℃), suitable for various process requirements.

Compliant with international environmental protection standards such as RoHS and REACH, it contains no heavy metals and has no irritating odor. It is suitable for use in fields such as food packaging and children's products.

Base material compatibility: Paper (cardboard, coated paper), PVC, PET, leather, fabric, etc.

Process compatibility: Various printing methods such as flat pressing, rolling pressing, and embossed pressing are available.

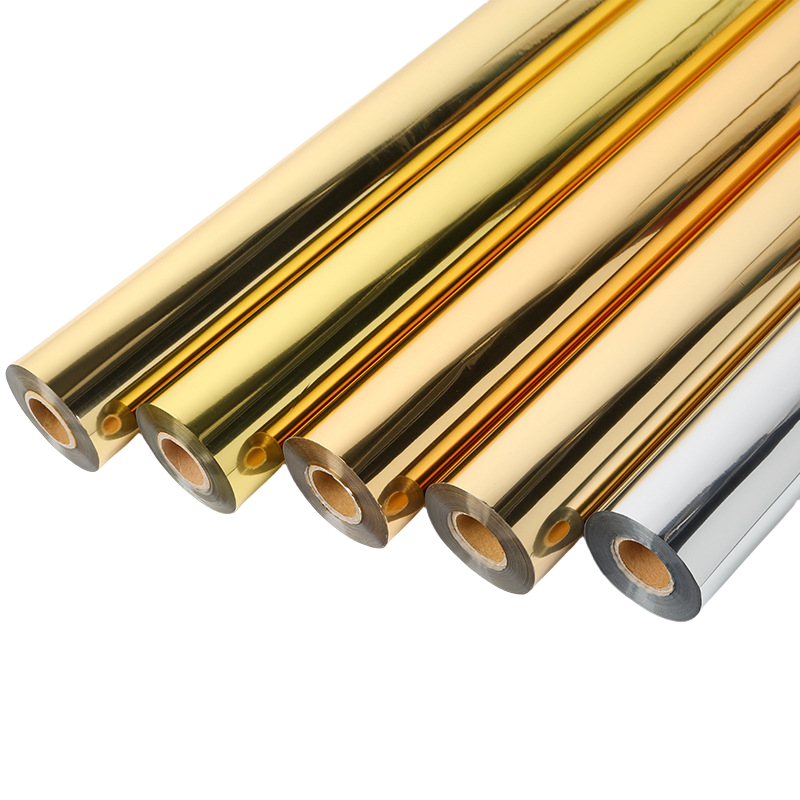

Electrolytic Aluminum Foil Paper Film Product

Application Scenarios

Luxury product packaging: Logo or border stamping on cosmetic boxes, wine boxes, and jewelry boxes.

Cultural and creative products: Decorative patterns for notebooks, bookmarks and greeting cards.

Accessories for clothing: Embellishments with gold stamping on clothing labels and patterns on shoes and hats.

Business Printing: Enhancing the details of high-end business cards, albums and posters.

Technical Specifications

Material:PET base film + aluminum coating + resin coating

Width:Standard width: 640mm/1020mm (customizable)

Temperature Range:-20℃~120℃

Sticking Temperature:Suggested 120℃~160℃ (adjustable according to substrate)

Sticking Speed :5-15 meters/minute

Service Support

Customization Service: Personalized customization of color, width, and pattern is available.

Technical guidance: Free provision of hot stamping parameter debugging and process suggestions.

Sample provision: We offer sample trials to ensure satisfactory results.

Conclusion: The multicolored foil stamping film, with lor expression ability and outstanding process adaptability, has become an ideal choice for enhancing product value. Whether it is for brand packaging orits unique co creative design, it can give it a sense of luxury and fashion. Welcome to contact us for consultation. We will provide you with professional solutions!

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

The Colorful Foil Paper Film seems easy to handle and gives a shiny effect, which makes this shop feel worth checking again.

This Colorful Foil Paper Film is great! Vibrant colors, sturdy, easy to use. Adds a nice shine to crafts. Highly recommend!