The thermal transfer rubber vulcanization label-specific ribbon is a high-performance transfer consumable specifically for rubber vulcanization labels (such as tires, industrial rubber products, automotive components, etc.). Through the high-temperature heat pressing process, the ribbon can firmly transfer clear and durable graphic and text information onto the label surface. Even when exposed to friction, oil stains, high temperatures, or outdoor environments for a long time, it still maintains excellent weather resistance and readability.

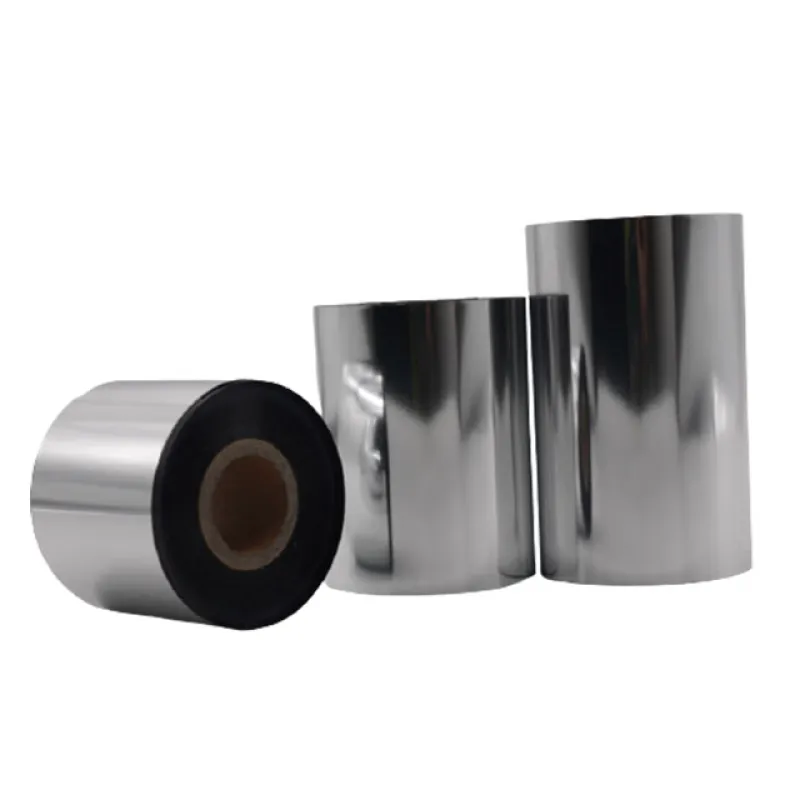

Product Review:Heat transfer rubber vulcanization label-specific ribbon

High performance and excellent weather resistance, specially designed for harsh environments

Product Overview

The thermal transfer rubber vulcanization label-specific ribbon is a high-performance transfer consumable specifically for rubber vulcanization labels (such as tires, industrial rubber products, automotive components, etc.). Through the high-temperature heat pressing process, the ribbon can firmly transfer clear and durable graphic and text information onto the label surface. Even when exposed to friction, oil stains, high temperatures, or outdoor environments for a long time, it still maintains excellent weather resistance and readability.

Core Advantage

Adding anti-sulfurization agents can effectively resist the erosion of sulfides (such as H₂S, SO₂, etc.), and even when exposed to sulfur-containing environments for a long time, the labels' graphics and text will still remain unchanged and not fade or fall off.

High-temperature resistant (up to over 200℃), resistant to oil stains, acid and alkali. Suitable for tire vulcanization, industrial production lines and other high-temperature and high-pressure scenarios.

Using a special resin-based ink layer, it is closely bonded to the rubber-sulfurized label surface. It is resistant to scratching and peeling, ensuring that the identification remains intact for a long time.

Black or color ribbons are available. The printing effect is sharp and it is suitable for printing fine contents such as barcodes and small fonts. The scanning recognition rate is high.

Compatible with mainstream thermal transfer printers (such as Zebra, Datamax, SATO, etc.), and supports various rubber label materials (such as PVC, polyester, special vulcanized labels).

Compliant with RoHS/REACH standards, free of heavy metals and harmful solvents, suitable for packaging and labeling in the food, medical and other industries.

Thermal Transfer Ribbon Serie

Technical Specifications

Base Material:High-strength polyester film (thickness 4.5 - 6 μm)

Carbon Layer Type:Resistant to vulcanization resin

Applicable Printers :Industrial-grade thermal transfer printers (such as Zebra, Toshiba, Bobst, etc.)

Printing Speed:Maximum support 8 inches per second (203 dpi)

Applicable Media:Synthetic paper, PET, PVC, matte silver dragon labels, etc.

Storage Period:Original packaging unopened for 2 years (avoid light, below 25℃)

Typical Application Scenarios

Automobile/Tire Industry: Tire vulcanization labels, rubber component traceability markings

Power cables: Long-term identification of cable models and specifications in sulfur-containing environments

Industrial rubber products: labels for products such as sealing rings, conveyor belts, shock absorbers, etc.

Outdoor assets: Weather-resistant labels for metal assets such as power towers and pipelines

Service Support

Support customized services (adjustment of width, length, and ink color)

Provide technical adaptation testing and printer parameter optimization solutions

Why choose our vulcanized color tape?

Professional formula: Optimized for rubber vulcanization process, with industry-leading adhesion.

High stability: High batch consistency, reducing the risk of printer tape jams or breaks.

Cost optimization: The transfer efficiency is high, and the number of labels that can be printed per roll is far greater than that of ordinary ribbons.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

This thermal transfer rubber vulcanization ribbon is reliable. The prints on rubber items are crisp, better than some others I’ve tried. It holds up well to regular use and feeds smoothly without jams. It’s reasonably priced for the quality, and I’ll likely order it again.

I tried the Thermal Transfer Rubber Vulcanization Ribbon for labeling rubber products, and it worked great. The print stayed clear even after the rubber went through heat treatment. Reliable and durable—definitely recommend for industrial use.