Struggling to print on dark or colored labels? Thermal Transfer White Ribbon makes it simple. Designed for thermal transfer printers, it creates bright white prints that stand out clearly and last over time. Perfect for barcodes, product labels, and asset tags, this ribbon ensures high visibility where standard black ribbons fail. Durable and reliable, it’s an ideal choice for industries that need professional results on non-white surfaces.

Product Review:Introduction to Thermal Transfer White Ribbon Products

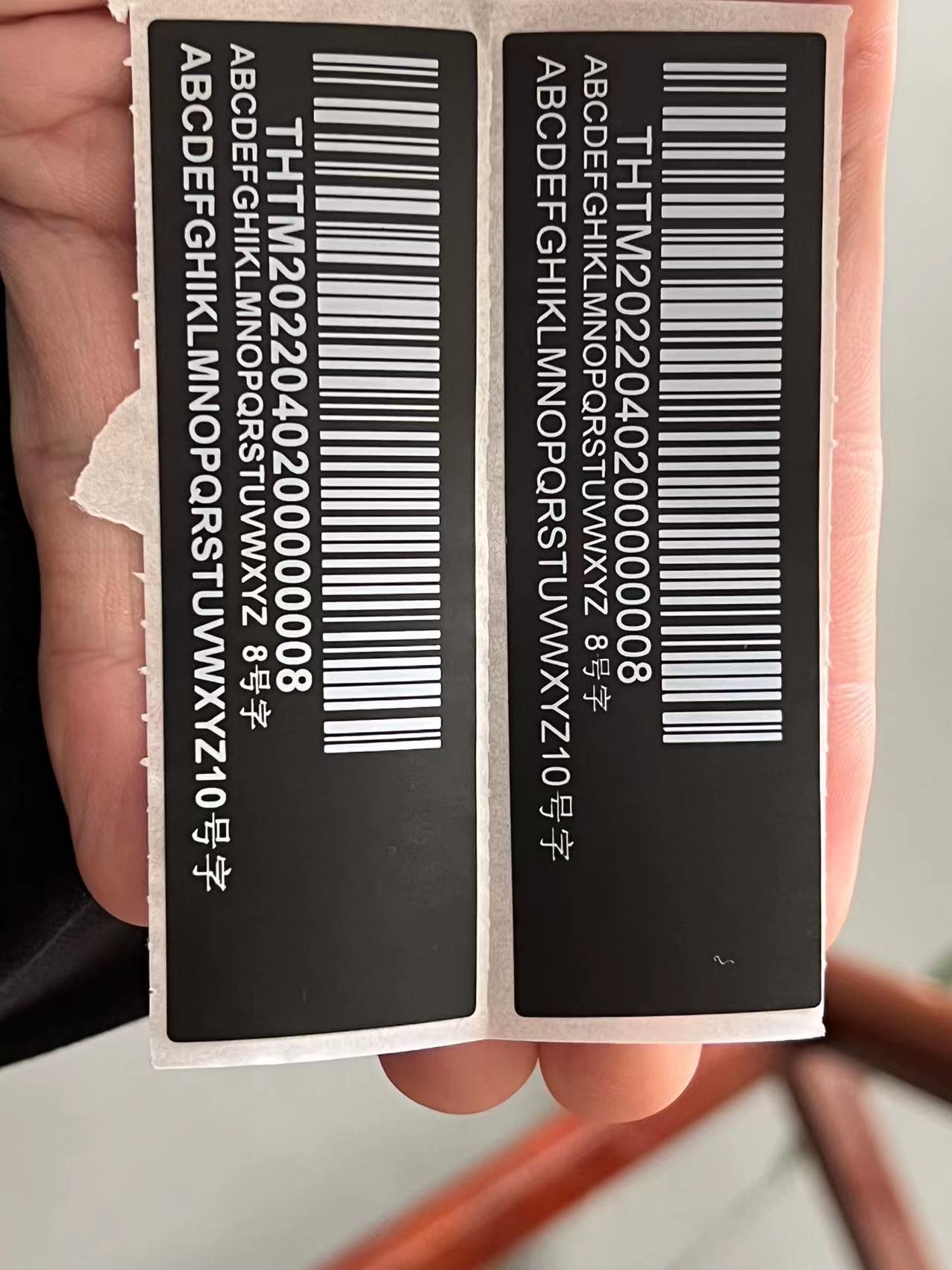

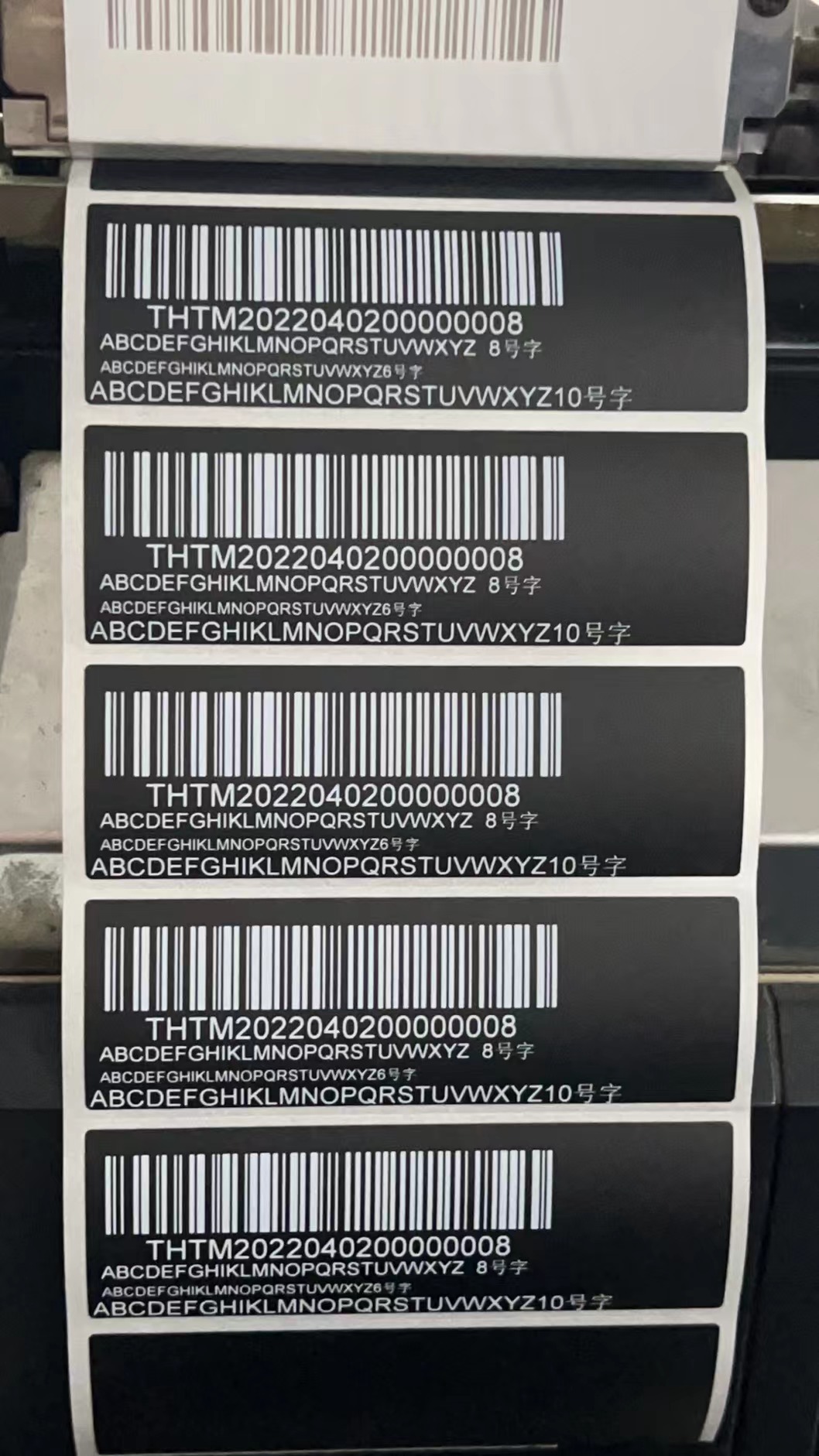

Printing on dark or colored labels can be tricky, but the Thermal Transfer White Ribbon from Ownlikes makes it simple and reliable. Designed specifically for thermal transfer printers, this ribbon creates bright, high-contrast prints that stand out clearly and last over time. Whether you're printing barcodes, product labels, or asset tags, it ensures high visibility where standard black ribbons fall short.

Product Overview

The Thermal Transfer White Ribbon is a high-performance printing consumable, specifically designed for dark or colored media. It’s made from high-quality resin-based or semi-resin and semi-wax materials. The unique white ink layer ensures clear and high-contrast graphic printing, even on dark labels such as black, red, and blue.

This Thermal Transfer White Ribbon is perfect for various industries, including electronics, clothing tags, and industrial identification. It provides high visibility and durability, even on non-white substrates, ensuring your labels, barcodes, and product tags stand out and remain legible for long periods.

Product Features

High White Ink Coverage: The Thermal Transfer White Ribbon ensures text, barcodes, and graphics are sharp and clear, even on dark labels, ensuring high visibility.

Scratch Resistant White Ribbon: As a scratch resistant white ribbon, it offers superior adhesion to materials like PET, PVC, fabric, and synthetic paper. It resists fading and smudging, ensuring long-lasting results.

Widely Compatible: Compatible with major thermal transfer printers, including Zebra, TSC, and Datamax, the Thermal Transfer White Ribbon works seamlessly with both flat-head and near-edge printing technologies.

Environmental Durability: The ribbon resists high temperatures, abrasion, and chemical exposure, making it perfect for use in industries such as logistics, warehousing, and manufacturing.

Eco-Friendly and Safe: This Thermal Transfer White Ribbon complies with RoHS and REACH standards, ensuring it is free of harmful substances. It's suitable for use in sensitive industries like food, cosmetics, and pharmaceuticals.

Thermal Transfer Ribbon Serie

Technical Specifications

Base Material Type: Resin-based / Mixed-based

Width Range: 20mm - 150mm (customizable)

Length Options: 300 meters / 450 meters (standard roll packaging)

Temperature Resistance: -20℃ ~ 150℃ (long-term storage)

Printing Speed: Maximum support of 8 inches per second (203 dpi)

Application Scenarios

Electronics & Electrical: The Thermal Transfer White Ribbon is widely used for black PCB board labels and cable identification, ensuring clear visibility even when printing barcodes on colored backgrounds.

Clothing Industry: This ribbon provides reliable results on dark fabric washing labels and brand tags. Its durable thermal transfer ribbon quality ensures it withstands frequent washing and wear.

Automobile Manufacturing: The Thermal Transfer White Ribbon is ideal for colorful component traceability labels and other high-contrast marking applications.

Special Packaging: Ideal for luxury goods anti-counterfeiting labels and cosmetic packaging, where durability and clarity are essential for brand protection.

Why Choose Ownlikes Thermal Transfer White Ribbon?

Exceptional White Coverage: Our Thermal Transfer White Ribbon delivers sharp, high-contrast printing on dark or transparent label surfaces, ensuring superior visibility and scan reliability.

Custom Sizes & Flexible Ordering: Choose from common widths like 30 mm, 40 mm, 60 mm, and 110 mm, or let us customize ribbon specifications to suit your specific needs.

Quality Guarantee: We conduct full-process quality inspections, with a print pass rate of ≥99.5%.

Technical Support: We offer expert guidance for printer parameter setup and after-sales tracking services.

Order Information

Model: R-B315 (Resin-based) / RW-B316 (Mixed-based)

Packaging Specifications: 10 rolls per box (can be negotiated)

Delivery Cycle: Standard products ship within 72 hours; custom orders require 7–15 working days.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(3)

I used the Thermal Transfer White Ribbon for some label printing, and it worked great! The print quality was clear, and the ribbon lasted longer than I expected. A solid choice for clean, high-quality labels.

Been using the Thermal Transfer White Ribbon for a few batches now—prints clearly and holds up well. No smears, no fuss. Does what it should, and that’s all I need

I’ve been using the Thermal Transfer White Ribbon for my label printer, and it works perfectly. The print quality is sharp and clear, with no smudging, even after long-term use. It’s easy to load and has a smooth transfer onto various surfaces. The white ribbon gives a crisp, professional look to my labels. Definitely a dependable product that I’ll keep using for my printing needs!