Thermal transfer color ribbon is a high-quality consumable specifically designed for thermal transfer printing technology. It is widely used in areas such as stickers, packaging, clothing tags, and electronic product identification. With precise color reproduction and excellent durability, the color ribbon can meet customers' demands for high-quality, multi-color printing, especially suitable for scenarios where brand image or product information needs to be prominently displayed.

Product Review:Introduction to Thermal Transfer Color Ribbon Products

Product Overview

Thermal transfer color ribbon is a high-quality consumable specifically designed for thermal transfer printing technology. It is widely used in areas such as stickers, packaging, clothing tags, and electronic product identification. With precise color reproduction and excellent durability, the color ribbon can meet customers' demands for high-quality, multi-color printing, especially suitable for scenarios where brand image or product information needs to be prominently displayed.

Product Features

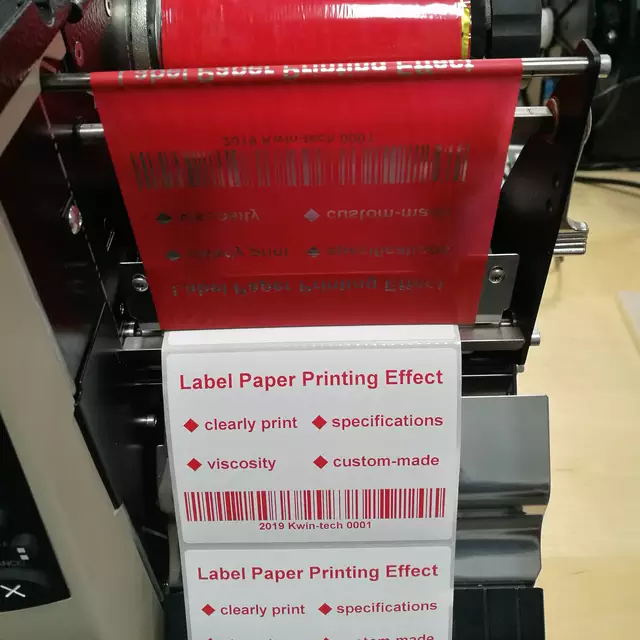

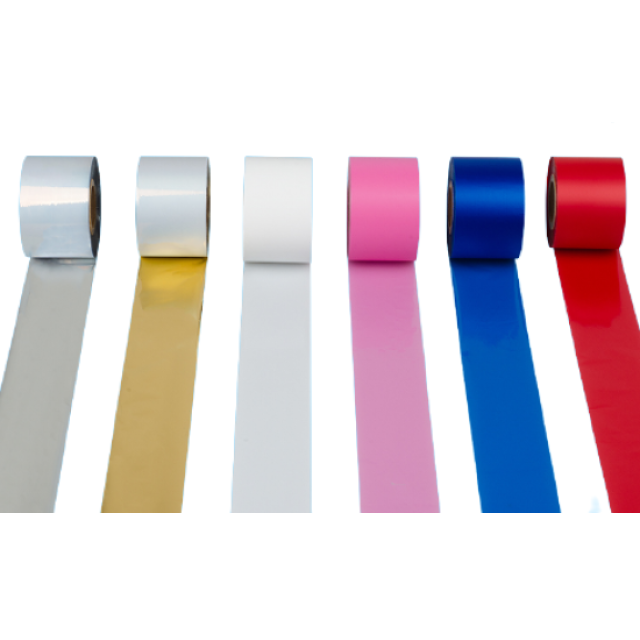

Offer a variety of standard colors (such as red, blue, green, gold, silver, etc.) as well as customized colors to meet the personalized printing requirements.

The colors are bright and rich, and the printing effect is clear and detailed, enhancing the visual appeal of the labels.

Compatible with mainstream brand thermal transfer printers (such as Zebra, SATO, TSC, etc.), applicable to various materials (copperplate paper, synthetic paper, PET, PVC, etc.).

High-temperature resistant and scratch-proof, ensuring that the printed content remains durable in complex environments.

Waterproof, oil-resistant, alcohol-resistant. Suitable for industrial, logistics, medical and other scenarios where the durability of labels is highly required.

Some models are designed for long-term outdoor use and are resistant to UV fading.

Compliant with international environmental protection standards such as RoHS and REACH, it is non-toxic and harmless, and suitable for sensitive industries such as food and cosmetics.

Thermal Transfer Ribbon Serie

Technical Specifications

Base material: High-performance polyester film (PET)

Coating: Special ink layer + Heat-resistant protective layer

Width range: 30mm - 110mm (Supports customized cutting)

Length: Standard 300 meters per roll (customizable)

Printing speed: Up to 8 inches per second (203 mm/s)

Application Scenarios

Retail and Packaging: Colorful product labels, luxury brand tags, promotional labels.

Industrial manufacturing: Equipment identification, color warning labels.

Logistics transportation: Multi-color classification labels, enhancing sorting efficiency.

Medical industry: Use color to distinguish between drugs or specimen labels.

Service Support

Offer sample testing services to ensure that the printing machine and material you choose are compatible.

Support OEM/ODM customization, including personalized requirements such as color, size, and packaging.

The professional technical team offers pre-sale consultation and post-sale support.

Why Choose Us?

10 years of industry experience, strict quality control system.

Fast delivery, high cost-effectiveness, service covering the global market.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I used the Thermal Transfer Color Ribbon for printing labels, and the colors came out really vibrant. It works well with my printer, and the print is sharp and long-lasting. Definitely a solid choice for quality prints.

I’ve been using the Thermal Transfer Color Ribbon for a few weeks now, and it works great. The colors come out sharp and vibrant, with no issues like fading or smudging. It’s easy to load and lasts a decent amount of time. A reliable product for my printing needs!