Polyimide anti-static high-temperature resistant tape is a high-performance tape made from polyimide film as the base material, coated with special high-temperature resistant adhesive, and treated with anti-static properties. This product combines excellent high-temperature resistance, anti-static function, electrical insulation, and mechanical strength. It is widely used in high-end manufacturing fields such as electronics, aerospace, semiconductors, and PCB (printed circuit boards), providing reliable protection for precision processing in high-temperature environments and electrostatic sensitive scenarios.

Product Review:Heat Resistant Tape Product Overview

Polyimide anti-static high-temperature resistant tape is a high-performance tape made from polyimide film as the base material, coated with special high-temperature resistant adhesive, and treated with anti-static properties. This product combines excellent high-temperature resistance, anti-static function, electrical insulation, and mechanical strength. It is widely used in high-end manufacturing fields such as electronics, aerospace, semiconductors, and PCB (printed circuit boards), providing reliable protection for precision processing in high-temperature environments and electrostatic sensitive scenarios.

Heat Resistant Tape Core Features

Long-term temperature resistance range: -40℃ to 260℃, can withstand temperatures above 300℃ for short periods without melting or shrinking.

It maintains excellent dimensional stability and adhesion at high temperatures, avoiding residue of the adhesive layer.

The controllable range of surface resistivity is 10⁶ to 10⁹ Ω/sq, effectively preventing static electricity accumulation and protecting electronic components from ESD (electrostatic discharge) damage.

Suitable for cleanroom environments, reducing dust adhesion.

Dielectric strength ≥ 5 kV/mm, stable insulation performance, suitable for high-frequency and high-voltage environments.

Strong and tough mechanical properties

High tensile strength (≥100 N/cm), tear-resistant and resistant to chemical solvents (such as alcohol, acetone, etc.).

It has good flexibility and can conform to complex curved surfaces or precise components.

Compliant with RoHS and UL certifications, free of halogen and toxicity, and does not release harmful substances at high temperatures.

Adhesive Tape Product Series

Heat Resistant Tape Typical Application Scenarios

Heat Resistant Tape Product Specifications and Parameters

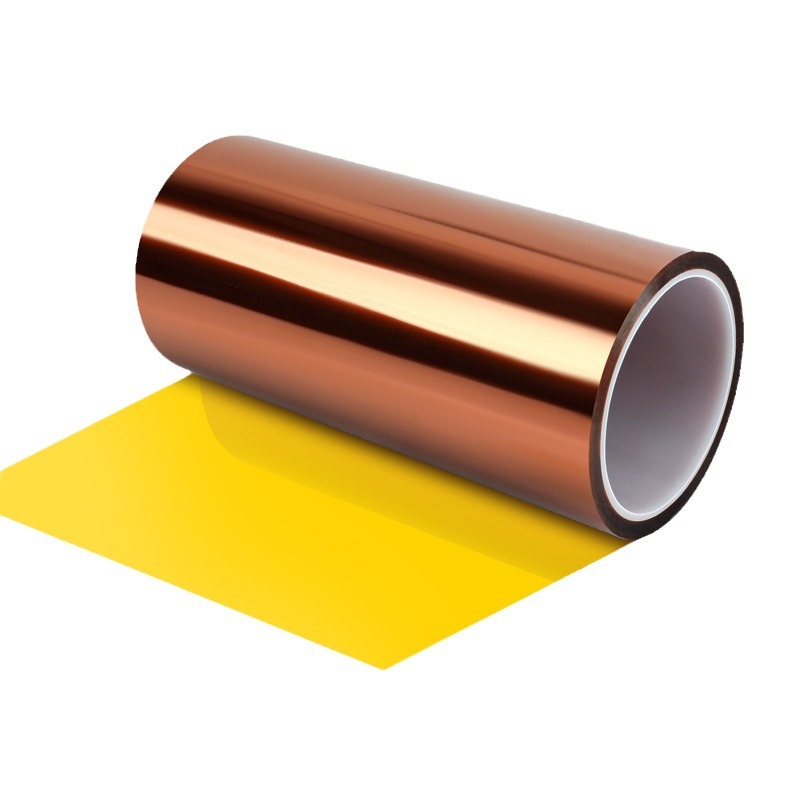

Base Material Thickness:0.025mm - 0.15mm (Customizable)

Adhesive Type:Silicone / Acrylic (High-temperature resistant)

Color:Amber / Black / Transparent

Length and Width:Custom slitting (Common width: 1 - 500mm)

Peel Strength:3 - 10 N/cm (Adjustable)

V. Service and Support

Customized services are supported (such as size, resistance value, adhesive type, etc.).

Provide professional technical consultation and solutions to help customers optimize their process flows.

Why choose our polyimide tape?

✅ Customization service: Flexible customization of thickness, adhesion, color and size is supported.

✅ Strict quality control: Certified by ISO 9001 quality management system, stable performance in each batch.

✅ Quick response: Provide technical support and sample delivery, feedback within 48 hours.

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(2)

I’ve been using Ownlikes Polyimide Heat Resistant Tape for weeks, and it holds up perfectly under heat. Highly recommend!

I used the Polyimide Heat Resistant Tape for a soldering job, and it held up perfectly. It stayed in place under high heat and didn’t leave any residue after removal. Strong, clean, and reliable—great for electronics work.