Conductive adhesive tape is a type of functional tape that combines high conductivity with excellent adhesive properties. It is made with flexible fiber fabric (such as polyester fiber or nylon) as the base material, with a high-conductivity metal layer (such as copper, nickel or silver) plated on the surface and a conductive or insulating pressure-sensitive adhesive coating on the back. It is widely used in electromagnetic shielding (EMI), grounding protection and electrostatic discharge (ESD) protection in fields such as electronic equipment, communication, aerospace, etc.

Product Review:Product Overview:

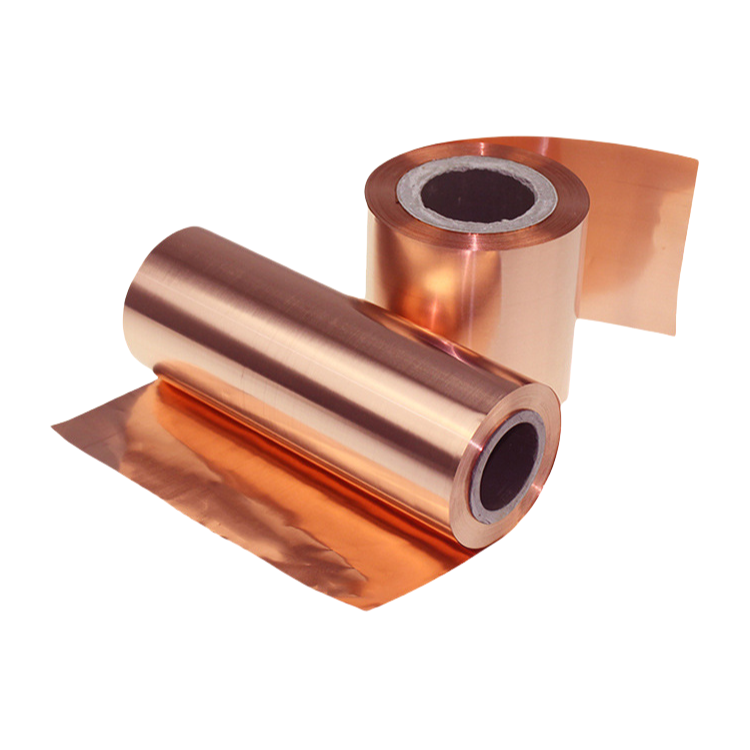

Copper foil tape is a functional tape made from high-purity electrolytic copper foil as the base material, coated with high-performance conductive or non-conductive adhesive. It features excellent conductivity, electromagnetic shielding properties, corrosion resistance, and flexibility. It is widely used in the fields of electronics, electrical engineering, communications, and automobiles.

Product features

The copper purity is ≥ 99.9%, and the surface resistance is as low as ≤ 0.05Ω/sq (the specific value may vary depending on the actual product). It can effectively conduct current or shield against electromagnetic interference (EMI).

The adhesive backing is made of acrylic or rubber-based adhesives, which have long-lasting adhesion and can adhere to various materials (such as metal, plastic, glass, etc.).

High-temperature resistant (-40℃ to 150℃), moisture-proof, UV-resistant, suitable for harsh environments.

Processability

It can be easily stamped, die-cut and folded, meeting the requirements for complex shapes.

We offer single-sided conductive adhesive, double-sided conductive adhesive, and various other specifications including those with release paper.

Technical parameters (example, please adjust according to actual data)

Copper foil thickness:0.03mm - 0.1mm (customizable)

Adhesive layer thickness:0.02mm - 0.05mm

Peel strength:≥10N/25mm

Resistance value:≤0.1Ω/sq

Temperature resistance range:-40℃ - 150℃

Application fields

Electronic industry: PCB board shielding, grounding protection, line repair.

Communication equipment: 5G base stations, internal electromagnetic shielding of mobile phones.

Automotive electronics: Battery pack shielding, wiring harness fixation.

Appliance sector: Electromagnetic leakage protection for microwave ovens and refrigerators.

Others: Building anti-static measures, DIY creative conductive connections, etc.

Instruction for Use

Clean the surface to be adhered, ensuring there is no oil or dust.

Cut the adhesive tape according to the requirements, remove the backing paper, and then gently press it onto the surface for adhesion.

To enhance the stickiness, you can use a roller to press or apply heat treatment.

Packaging and Storage

Packaging: Roll form (width selectable from 5mm to 500mm), each roll length is 5m to 50m.

Storage: Store in a cool and dry place, away from direct sunlight. Shelf life: 12 months.

Quality Certification

Complies with international standards such as RoHS, REACH, UL, etc. (Fill in according to the actual certification.)

If you have any questions about our head Stickers material products, please feel free to contact us.

Customer Feedback(3)

I used the Copper Tape Material for a small electronics fix, and it worked well. It conducts electricity properly and sticks firmly to different surfaces. It’s easy to use and does what it’s supposed to do.

I used the Copper Tape Material for a DIY electronics project, and it worked perfectly. The adhesive is strong, and the conductivity is reliable. Plus, it’s easy to cut and shape—made my setup way cleaner and more efficient.

This Copper Tape Material is perfect for my electronics repair projects. The adhesive is strong and sticks well to various surfaces, and the conductivity is excellent for grounding and EMI shielding. It’s also easy to cut and apply, even in tight spaces. Definitely a must-have for DIYers or anyone working with circuits.